The computer industry is careless of history. It may have utterly changed our lives through digitization, but in the process it has neglected its own records. The first true computers were an achievement comparable to a Moon landing, but in some cases, nothing remains of them.

Back in 1949, EDSAC was probably the first truly practical computer to go into everyday use. It spawned the first successful commercial computers and the first software libraries. But sixty years later, when engineers and historians wanted to understand it, they had a problem: there were no proper records of how it worked.

“It was a giant jigsaw puzzle with half the pieces missing,” says Andrew Herbert, the retired computer scientist who for a decade has led a project to rebuild EDSAC at the UK’s National Museum of Computing in Bletchley.

The original EDSAC was built from vacuum tubes and stored data in tubes of mercury, before semiconductors enabled silicon chips. Within a decade, it was replaced, and the original machine was scrapped. All Herbert’s team had to work on was a set of photographs and a few notebooks.

Birth of an era

In the aftermath of World War II, the potential of electronics was obvious. Radar had won aerial battles, while Bletchley Park’s Colossus automated codebreaking, rendering the German Enigma code transparent, and shortening the war.

But Colossus was hardwired for its wartime work; scientists and the military wanted a new generation of systems to tackle different jobs. Ideally, they wanted systems which could be applied to any problem.

US wartime computing program produced ENIAC. It was a general purpose system, but it was delivered too late to help against the Nazis, and it had to be physically rewired to run different programs.

The US government held a tech summit, and invited experts from Britain. Visionary computing pioneer John von Neumann wrote notes on the next steps. He suggested systems which could load programs from a data store, and the race was on.

The “Baby” system from Manchester was the first to run stored programs in 1948, but that was just a test. The first successful general purpose computer arrived in 1949 in Cambridge: EDSAC, or Electronic Delay Storage Automatic Calculator.

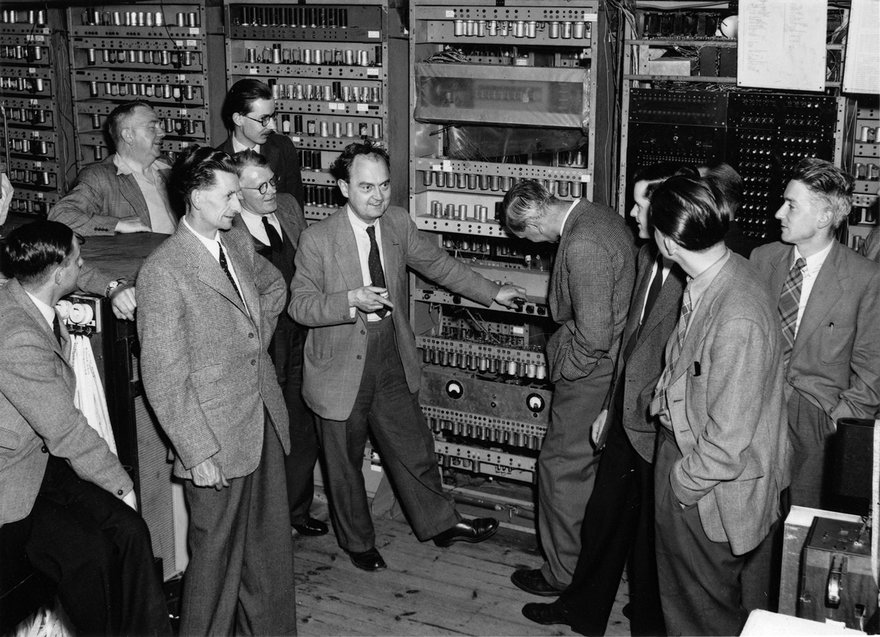

Built by Professor Maurice Wilkes at Cambridge University’s Mathematical Laboratory, EDSAC was supported by a small team of technicians, and performed calculations for scientists. In its short life it helped three of them win Nobel Prizes.

It also supported the foundations for the theory and practice of computing. EDSAC saw the invention of the subroutine and the creation of the first software library.

Its logic was built from thousands upon thousands of vacuum tubes, wired by hand into metal shelves in six-foot racks. It consumed 11kW of power, and performed 650 instructions per second. Its memory, held in vibrating tubes of mercury, amounted to about 1kbyte in today’s terms, although it was arranged as 512 18-bit word, instead of today’s bytes.

Data was fed in on paper tape, and the results came out on a teleprinter, with a cathode-ray tube display to show the status of its memory.

“Maurice Wilkes wanted something which could do calculations that would otherwise have required paper and pencil,” says Herbert. It performed calculations far faster than a human could, and rapidly became a University workhorse.

In 1949, it ran its first program - a square root generator created by Beatrice “Trixie” Worsley, the world’s first computing PhD. in 1951 it found the world’s largest (79-digit) prime number, and in 1952 Sandy Douglas created the first video game, allowing operators to play noughts-and-crosses (tic-tac-toe) on EDSAC’s cathode ray tube display.

By July 1958, it had been superseded by EDSAC 2. All work shifted to the new machine, and EDSAC was unceremoniously decommissioned. It was stripped of its parts, and its metal framework was scrapped.

Before its demise, EDSAC had revolutionized academic computing - and also kicked off commercial computing as we know it today. British restaurant chain J Lyons & Co sponsored EDSAC, and its LEO 1, the world’s first business computer, was developed from the EDSAC design.

The story begins

It was 2011 when the National Museum of Computing at Bletchley Park announced a unique project. It would build a working replica of EDSAC, in a project funded and inspired by Cambridge entrepreneur Hermann Hauser.

Hauser had helped found Acorn Computers (famous for the BBC Micro), as well as other tech companies including ARM. But as a PhD student he had worked with EDSAC veterans, and knew its significance.

In 2010, he asked former Cambridge professor David Hartley if EDSAC could be rebuilt. Hartley thought it was impossible, but Hauser pushed, asking: “Why don’t you find out and let me know?”

Andrew Herbert, one of the Museum’s trustees, was the obvious person to get on the possible project. A Cambridge computer scientist, he lectured under EDSAC designer Maurice Wilkes in 1978, before a career in which he led the Microsoft Research lab in Cambridge and then EMEA head of Microsoft Research, finally retiring in 2011.

It rapidly became clear this was not a simple job, but emphatically worth doing, says Herbert: “We’re getting a better understanding of our computer heritage, and celebrating a triumph of British computer technology.”

It’s been one of the greatest retirement projects imaginable for Herbert: “It’s men in a shed. It’s the pleasure of still using your brain, and learning new skills - even for those who are very experienced.”

Working from scratch

Given the task of making a computer, the original EDSAC builders worked from scratch. A group of radar and radio engineers accustomed to analog electronics, they were pioneers who invented digital thinking.

With almost no records to guide them, the reconstruction team had to go through that same process, working out how antique analog circuits could produce digital results.

The reconstruction process has taken ten years so far, while the original EDSAC was built in three years.

Herbert explains that the pioneers had huge resources by the standards of the day, and a large team: “The original team were steeped in radio and radar technology, and worked six day weeks with a full budget.”

The reconstructors are part-timers, and they have had to think their way into the pioneers’ minds and then rebuild infrastructure they needed to make the systems again. “We are working with volunteer labor. You get a day or a day and a half from people, and you can only work on one bit at a time.”

Some of the volunteers are people in their 80s: “They had their first contact with electronics in National Service.”

In 2012, when Herbert’s team started work, nothing of EDSAC survived. The whole machine had been taken apart and unceremoniously scrapped when EDSAC 2 replaced it. It wasn’t seen as a valuable object, just a stepping stone, explains Herbert.

The traces that remain are random, notebooks, diagrams and photos - and some of them are self-contradictory.

“There are some photos, but you can’t tell which are from the final or the early days of EDSAC. There’s very little about the physical construction or actual engineering. This has been worked out from scraps of evidence.”

One issue was that the EDSAC was not a single object, with one design. It changed as the pioneers built it, and changed further during its life. New ideas replaced older ones and sections were improved and rebuilt.

It quickly became clear that the reconstruction team had to make decisions. It wasn’t possible to make an exact “replica."

Instead, the team agreed a goal. The reconstruction would be a working system, which could be maintained by the staff and National Museum of Computing and seen working by visitors. It would use the original designs and detective work in the same 1950s style, and use 1950s technology where possible.

These groundrules mean that the reconstructed system has to be more reliable than the original, Herbert says. The analog systems of the original EDSAC could drift out of alignment, and it needed constant tweaking: “EDSAC was operated by a well trained cadre of [female] operators, who adjusted settings to keep it stable.”

That won’t be possible in a museum: “The staff are enthusiastic, but they have other work to do, so it must operate without constant tending.”

When it is in use, the EDSAC reconstruction will have modern sensors monitoring its vital signs, and warning if adjustments are needed.

Memory issues

The team had to change some aspects of the design for the modern world.

“The original design had exposed mains wiring and poor earthing,” says Herbert. “Health and safety hadn’t been invented then."

But there were other fundamental problems. The main memory used mercury delay lines, which store information as sound in a standing wave on a column of mercury.

The technology had evolved from wartime radar systems, and was introduced to early computers by J Presper Eckert, using mercury because of its ideal acoustic properties.

However, not only were mercury delay lines unreliable, mercury is poisonous, but that wasn’t the only problem.

“In fact with mercury, the issue wasn’t health and safety,” Herbert explained. The tubes could have been filled carefully, and drained and reassembled every couple of years, but there was another issue: “That much mercury would cost £160,000 ($221,000) on the open market. We didn’t have that in the budget.”

Keeping with the spirit of 1950s technology, Herbert’s colleagues had a suggestion: if they couldn’t use mercury, why not use a later evolution of the technology?

Later in the 1950s, mercury memories were replaced by solid nickel wires, and these “torsion wire delay” memories stayed in use until the 1960s.

“We used nickel delay lines - we wanted something authentic, but easy to maintain,” explains Herbert.

They were still obsolete 50 years ago, however, and the team had to rediscover how to make memory systems. But their behavior was easier to predict and reproduce.

The hard work started with the basic structure of EDSAC. It was built from racks, each of which hold 13 “chassis” pieces, shelves made of folded sheet metal. Each chassis held thermionic valves (vacuum tubes), plugged into sockets and interconnected with wiring and passive components (capacitors and resistors).

Reconstructing these basic modules was going to be a struggle, because they didn’t exist any more. “The original machine was sold off for scrap,” says Herbert.

Luckily, one chassis had escaped destruction: “Someone bought a rack to make bookshelves, and this guy took a chassis to scavenge and never got round to it.”

Sixty years on, this chassis emerged from a shed - one of several lucky breaks for Herbert: “You never know what is going to turn up.”

Detective work

The EDSAC team know how to make new chassis modules for the system, but what should they put in those new shelves? The valves were visible, but the wiring was hidden under the folded metal, and the photos did not show it.

Luckily the photos were high quality, and could be magnified. “Magnify the photos, and you can see a label, which might say ‘half adder,' says Herbert. With deduction and reverse engineering, we had to ask what are the circuits which would do that?”

The team knew digital electronics, and how to build basic functions like AND and OR gates. They established some templates and had another stroke of luck - some hand drawn circuit diagrams turned up for two of the chassis modules, which gave the team an idea of the kind of circuits the pioneers had used.

They also had handwritten notes which outlined the functional breakdown of the system.

Finally, the photographs helped, because the types of valve were visible, and the team could puzzle out what they might be for: “We could recognize patterns in the layout of valves,” says Herbert. “Things which are connected together, would be put close together.”

Looking at the photos, the team started to see AND gates and amplifiers, and recognized higher functions like adder circuits: “It was mostly a bottom-up process,” says Herbert. “We knew from some written documents what functions there were.”

The team knew what it was looking for but didn’t know the route there: “It was like a jigsaw puzzle. By the time you’ve got near the end, it’s obvious where the last pieces go.”

The modular design helped too. Like modern systems, EDSAC used blocks of technology to do particular jobs, and replicated them: “There’s one chassis which is repeated 43 times, making up about a third of the machine.”

You can tell Herbert is pleased with the detective work: “Obviously, it’s quite likely there are bits of our EDSAC which weren’t part of the original. But we know each part has the same function and works the same way, and where we can see a chassis, ours is identical.”

Army surplus valves

There were more compromises to be made in the construction process. After a lot of discussion, the team set themselves what sounds an ambitious goal: to build the logic entirely with traditional vacuum tube valves - because that seemed to be the essence of the original machine.

On the face of it, this sounds insane. These valves haven’t been used in computers for 60 years. They were famously unreliable, and were replaced by transistors in the 60s. Surely there can’t be enough authentic 1950s valves available after 70 years?

Surprisingly, there are plenty: “In terms of parts, there enough valves out there to build another three EDSACs - or to keep this one going for many years,” says Herbert, proudly.

“These valves were in radar systems from the 1940s to the 1960s,” he explains. During this time, manufacturing improved and reliability went up.

Plenty of these valves were made, and they survive because of the vagaries of military procurement: “Governments always over procure in spares, and when the systems are withdrawn, the spares all go out to surplus dealers. They have them in a hangar, waiting for a call from me!”

Herbert clearly enjoyed his negotiations with military surplus dealers: “The dealer would say the valves should be expensive because they are rare,” he says. In return, Herbert would point out that there were literally no other buyers for them.

The EDSAC storeroom soon filled with valves, still in their original cardboard packaging. “They’re in good condition considering they’ve in a box for 60 years, though some have deteriorated.”

A wiring compromise

In the wiring underneath the shelves, it was a different story. 1950s resistors and capacitors can still be found, but the team made the decision to use modern passive components, which are smaller and more reliable.

“Some people were uncomfortable when we decided to buy modern capacitors and resistors,” he says. “We get given old ones, and they are the right shapes and size and color, but they drift out of spec. If we’d gone down that path, it would have given us huge reliability issues.”

Using 1950s capacitors and resistors would have meant another storeroom for those components and a continuous headache for the Museum when it would eventually operate the system, adding massively to the maintenance required.

In Herbert’s view, the modern resistors still keep faith with the spirit of the project, as the same wiring circuits are used: “Fundamentally, providing it’s a 100k resister it doesn’t matter whether it is modern, and the size of an ant, or a 1940s unit the size of a finger.”

There was another small problem in putting the shelves together. While the project had components, for the circuitry, and valves, it could not get valve holders. In the 1950s they did not wear out, and spares weren’t kept.

“The hardest thing to get was the valve holders,” says Herbert. “In the end we got them made in China. They cost a penny each and we got thousands.”

The team sent a specification to China, but it wasn’t plain sailing. “They all came back a little bit tight,” Herbert explains - so he had to make adjustments to around 12,000 sockets. “I spent many happy weeks with a hand drill and a little burr.”

It’s the kind of engineering which is unknown in computers now, but vitally important for the EDSAC team. Badly fitting holders would be an Achilles' Heel, says Herbert. If the fit is too loose it invites corrosion on the legs of the valves, or loose connections needing constant waggling.

Finishing that stage of the project was something of a relief, and the EDSAC reconstruction now has enough spares for 20 years.

A message from the past

“During the build, we were going up the same learning curve as the pioneers,” says Herbert.

Much like their forebears, the team built the replica EDSAC one subsystem at a time, but they had one major benefit: as each subsystem was constructed, it could be tested against a digital simulation of the whole of EDSAC.

The first fundamental part to make was the heart of the system the clock which provides a digital pulse to synchronize different parts of the machine. This was vital, given that the behavior of the analog parts of the system could vary wildly.

At every stage, the reconstruction team had to deal with noisy signals, struggling to get the system to give a clean digital voltage.

One big issue was the use of monostables or “monoflops," which produce a predetermined pulse signal. EDSAC was originally built with monostables, but the reconstruction team found they were unreliable, drifting off their settings.

Reluctantly, they shifted to using bistables or “flip-flops” which switch between two stable states: “We found in several situations, we couldn’t make monostables work as well as we wanted.”

Unexpectedly, the decision was vindicated, years into the project: “A chap turned up, who was actually one of the engineers at Cambridge who joined just after EDSAC was decommissioned. One of his first jobs was to clear out cupboards, including the EDSAC schematics. He came to the computer museum, and said ‘I think I’ve got these drawings in my attic’.”

Looking at these designs from late in the life of EDSAC, they found the original pioneers had also switched to flip-flops: “We’ve been following the same path,” Herbert realized. “All these diagrams had bistables where we’d had monostables.”

“Some of the drawings exactly corresponded to our design, some had significant variations, but in all cases, the differences were in parts of the machine we weren’t happy with. Where the drawings mismatched, it was evidence of progress in design.”

The team was very glad to have this message from the original EDSAC pioneers, though a bit frustrated, because they’d had to make the decision on their own. “Going to bistables accelerated our progress. If we hadn’t done that would still be fighting the same problems.”

A more reliable EDSAC

The team built an EDSAC that was as close as possible to the original, but it didn’t reject the use of modern tools in building it.

The pioneers used oscilloscopes and voltmeters which were new technology and still primitive. The reconstruction team had Arduino modules, laptops, simulators and modern signal analyzers.

They’ve been able to make sure each module works by testing it against simulations based on what the logic designers in the team came up with. “The logical designers’ work remains pretty solid - considering it was done by someone reading historical records which were incomplete.”

“I think in some ways we may end up with a more reliable EDSAC than the original machine,” Herbert believes. “We’ve not been building it in the rush the pioneers were, and we have better diagnostics. It will be better tuned and we can diagnose problems more deeply.

“They didn’t have logic analyzers, or Python code to crawl all over the traces and compare them with the formal logic."

The modern team uses a simulator to generate logic traces, which can be compared with actual readings from inside the reconstructed machine.

The use of valves continues to push the team back to the basics, away from the “Lego” world of transistors and microchips.

“EDSAC is not Lego: you have to treat it as a big complicated machine,” he explains. “The signal can be soft and squishy. It climbs up a ramp, you get echoes and a ringing effect. It is tough to get good clean pulses.”

The pioneers used a signal level (a logical 1) that was any voltage above 20V. “In some parts of the machine it was 40V or 50V. Sometimes it would drop down to 15V. Sometimes it would work, and sometimes it wouldn’t.

To build any part of the system, the team has to start with the signals: “The start of commissioning is getting respectable signal voltages, with sharp enough edges. Then it comes down to timing issues.”

The team could build the processor and arithmetic units as autonomous systems, but they had to be synchronized: “There’s a lot of low level electrical stuff, but once we’ve got that sorted, it springs into life.”

Final stages

Work continued during the pandemic in 2020. The museum was shut, but work was distributed.

“Teams took home a chassis to work on and, when they could, they reassembled them,” Herbert recalls. “Groups collaborated through Zoom calls into the museum. So instead of the whole team gathering inside the machine, one was inside while the others linked from home.”

During the easing of restrictions in March of 2020, volunteers put a large part of the machine together, and it worked for the first time: “It came back with the answer to the problem they were working on in December.”

The project is now in its final stages. All the modules have been built and tested, and the machine can have runs of up to a couple of hours: “That will meet our need for demonstrating it in the museum.“

But integration isn’t simple: “Several parts of the machine are independently clocked from each others, and have to be brought into synchronization,” he says. “You can be held back for a whole cycle - we wouldn’t tolerate that in a modern computer design!”

Herbert expects to spend a busy summer getting the machine working properly before opening to the public later in the year.

“Our next milestone is when we successfully are able to execute all the arithmetical and general instructions in the instruction set,” he told DCD early in 2021. “We are about halfway through that. We’ve knocked all the big bugs out of the machine.”

The group is still learning. “As we commission the machine, we’ve discovered some things are redundant. Sometimes you don’t need amplifier states, for instance. There are some valves that aren’t doing anything - and we suspect that was the case in the original!”

The next step is to get the entire instruction set working, and then to operate using the delay lines for memory. “The delay lines have been built and tested standalone, so we anticipate that being fairly straightforward.”

Eventually, the machine will operate with its traditional input and output via paper tape and a teleprinter. The “initial orders” have been coded onto tape: “That’s like a boot ROM.”

“Then we will be done,” says Herbert. We will have achieved the brief of the replica project.“

Life support

But the story won’t stop there, because the Museum will then have the issue, as Herbert puts it, of “how to keep the damn thing going.”

The reconstruction team has had an incredible depth of experience to draw on, including experts like Peter Lawrence, and chief designer Chris Burton, who worked for Ferranti in Manchester from the 1950s, designing systems like the Pegasus.

The group has had a huge spirit of camaraderie, and drawn in pioneers like the early programmers Margaret Marr, Joyce Wheeler and Liz Howe, all of whom shared memories, checking and approving aspects of the final design.

But that team won’t be available once the machine is handed over to the museum.

“At the moment you need experts to maintain it,” says Herbert, but that won’t be feasible in the museum, so the restorers will be handing their recreated system over with its own life support system.

A small group is looking at creating monitors using modern gadgets like the Raspberry Pi which will track signals from the system. Ideally, these will be able to help museum staff troubleshoot, issuing instructions like “Change valve five on chassis six.”

That’s an intrusion of modern technology but is entirely appropriate, he says. “We’ve chosen not to compromise on how EDSAC itself works. It’s as authentic as we can make it. But we’ve had every luxury we can afford on how we build and monitor it.

“If you were keeping an elderly genius alive, you would use every medical technique.”

The meaning of it all

In the end, what is the significance of this achievement? EDSAC will run at around 650 instructions per second, and consumes around 9kW of power. Today, the average phone goes more than a million times faster than that on a tiny power budget.

But EDSAC was revolutionary for its time, Herbert points out: “That’s 1,500 times faster than a post doc with a hand calculator.”

And it appeared at a time when computing was developing fast, and no one was sure where it would lead.

“Cambridge was building a machine to work in the maths lab. They wanted to evaluate it to see what a proper computer could be like. They were surprised by how useful it was and how long it kept going.”

It could have been forgotten completely, he says: “Once EDSAC was working they were fed up with it. It was built to be a service machine. It was handed over as a working service, with an engineering team around it.”

The team who built it were excited to move on to EDSAC 2, which made a big step, using a bit slice design instead of EDSAC’s monolithic architecture.

“EDSAC 2 used several identical chassis to handle one bit on each one. EDSAC 1 was monolithic. If one chassis blew up, the system was broken. With EDSAC 2, you could pull in a spare one.”

EDSAC 2 also took software deeper. “EDSAC 1 was hardwired, but EDSAC 2 was microprogrammed so they could try out new instructions. “

But many of the founding ideas in practical computing flowed from EDSAC. It allowed libraries of subroutines: “That was well done, it was a long while before other machines had such a well designed interface. Others needed machine code, but Cambridge programmers didn’t have to know machine code.“

“It wasn’t the biggest, the fastest or the best engineered,” Herbert sums up, “but it changed the world more than the others.”

It kicked off commercial computing in a big way, through the involvement of the J Lyons and Co restaurant chain.

Lyons senior management recognized that admin costs were eating away at their margins, and wanted to automate receipts and inventory. They heard that computing was happening in America, and visited the team building Univac, who suggested that EDSAC might be a better fit for them.

Lyons provided an engineer, and funding which helped get EDSAC built, and then built its own machine, LEO. It was the first computer in the world to work on commercial applications, and was a clone developed from EDSAC.

Herbert hopes the project will revive disappearing expertise and inspire students to learn about the technical challenges of the pioneers, creating a living educational resource for students.

“As we have our struggle to work with EDSAC and to get it working, I think back to the pioneers led by Wilkes. They didn’t have modern laptops signal analyzers and Zoom to help them do the work. They had quite simple early oscilloscopes and voltmeters, and we wonder how they went about debugging the machine.

"They didn’t even have the knowledge that we had - that it would eventually work. For them at times it must have appeared to be very, very daunting. And, of course, they had no previous experience of building a computer - the team had come from various backgrounds of radar, instrument making, radio, and so forth.”

For Herbert, it’s been exciting: “We are privileged that we know how EDSAC works.”