The EU refrigerant regulation is urgently necessary for the protection of our environment. The emission of refrigerant gases into the environment – due to incorrect disposal or unintended leaks in the system – adds to the greenhouse effect. That is why refrigerants containing CFCs have already been withdrawn from circulation. Today’s refrigerants may no longer be comparable with these, but their potential for harm cannot be ignored. Therefore, a step-by-step phase-down in refrigerants with a high GWP (global warming potential) is the next logical – and necessary – step.

At the same time, we shouldn’t forget that the F-gas Regulation can be a force for innovation: experience from this and other areas shows that new legislation has always promoted technological advances. The outside pressure compels both plant operators and manufacturers to get to grips with sustainability and the efficient operation of their systems and machines.

The Regulation does come with disadvantages for manufacturers and plant operators, however. One of these involves the substitute refrigerants now on the market. A low GWP means that the refrigerant degrades rapidly as it enters the atmosphere. The only way to ensure this is to make it chemically reactive. However, high reactivity often means high flammability, entailing safety risks for people and machines – when using propane and butane, for example.

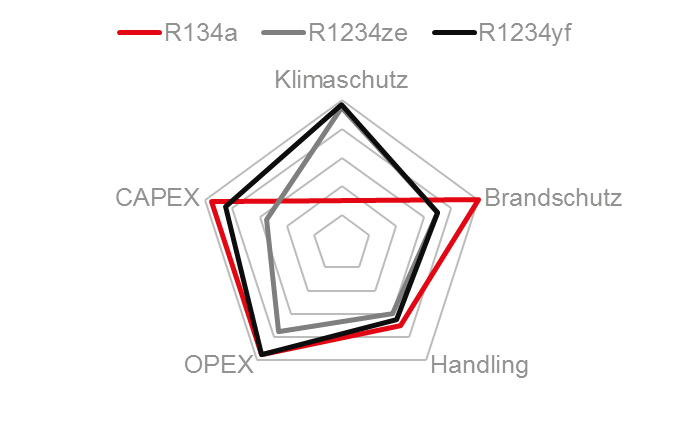

There are of course products with both low GWP and relatively low flammability. But these also have disadvantages. F-gases R1234yf and R1234ze satisfy both these criteria, for instance; but R1234yf is out of the question for us, firstly because it belongs to a different fluid group and reacts with water to form hydrofluoric acid; secondly, because its sparsity on the market makes it too expensive at present.

Stulz’s refrigerant of choice is R1234ze. To ensure compliance with the F-gas Regulation, we have specially modified the CyberCool 2 to work with this refrigerant. However, R1234ze has a low volumetric cooling capacity. Consequently, a chiller that originally delivered a cooling capacity of 1000 kW over a defined area now achieves just 750 kW over the same area. Energy consumption also falls, so energy efficiency is not negatively impacted. But the customer has to install a larger machine to cope with the same refrigeration demand.

This disadvantage may not be too serious in new data centers that are to be built in less populated areas, because of the more generous space available. However, existing data centers or industrial plants located in urban centers have to manage with the space available to them. Here, a larger footprint can lead to significant problems for their infrastructure and budget.

Market and trends

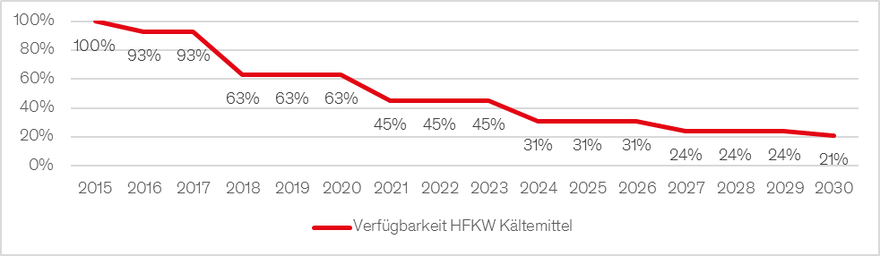

It is absolutely certain that the price of refrigerant will rise significantly, due to the phase-down adopted by the EU. From where we are standing, we cannot yet tell when the next noticeable price rise will be. We would actually have expected a price increase in 2016, following the announcement of the F-gas Regulation and the associated cuts in supply. We assume that the price increase was delayed to 2017 because users had stocked up in advance. It is impossible to estimate how much refrigerant plant operators, manufacturers and suppliers currently have in stock, and so a delayed price adjustment may again take place in 2018 with the next cut in supply.

Plant operators and manufacturers need to look at alternatives and modifications right now, because the next cut of 30 percent (Fig. 2) will have a significant impact on prices.

Here at Stulz, for example, we are considering delivering units destined for use in non-EU countries without refrigerant. Our customers will then be able to purchase the refrigerant they need at lower prices on their local market.

This is of course not a long-term solution, both where the price of refrigerant is concerned, and from an ecological perspective. Therefore, we continuing to research and develop, so that we are prepared for the future, and able to offer solutions that are good for our customers and the environment.

Natascha Meyer is a product manager at Stulz GmbH, specializing in chillers

For more information about the potential refrigerant shortage, read our feature, originally published in the June/July issue of the DCD magazine