It’s fair to say that all avenues are being explored to get energy into data centers and distribute it around them, combatting resistance and compressing energy into ever denser racks.

A team of researchers has come up with an extreme solution: Wiring up facilities with superconductors.

Superconductivity is a phenomenon, first observed in 1911, in which some materials have zero electrical resistance. As resistance is a limiting factor in how much current a wire can carry, this sounds like a Holy Grail for electrical engineers. A superconductive wire won’t heat up, won’t waste energy in resistance, and can carry much more current in a narrow space than a conventional conductor.

The problem is, that superconductivity was first discovered at temperatures close to absolute zero (0°K, or -273°C), making it completely impractical for widespread use.

In the following years, scientists searched for useful materials which would be superconductive at higher temperatures. Despite years of research, there are no “room temperature” superconductors, but since 1986, “high-temperature superconductors” have been discovered.

In 1986, Johannes Bednorz and Karl Müller of IBM showed a copper-oxide compound that was superconductive at a temperature of 35°K (a relatively balmy -238.15°C/-396.7°F). That was enough to win them the next Nobel Prize for physics, and kick off a race. The current record for superconductivity is a temperature of around 140°K (-133.2°C/-207.7°F).

That 140°K is still a chilly -130°C, but it’s a temperature higher than the -200°C (-328°F) boiling point of liquid nitrogen. Practical superconductors have to be supercold, or they “quench” and abruptly lose their magic. Still, liquid nitrogen can be bought for around $2 per liter, so engineers have stepped in and produced superconducting wires and cables.

Superconducting electromagnets are well established - they support a much higher current than regular devices and are used in science experiments, such as the Large Hadron Collider at the European particle physics laboratory CERN, and in fusion experiments. They are also used in more widespread magnetic resonance imaging (MRI) scanners.

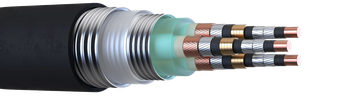

But electromagnets have tight coils which can be fully immersed. Actual superconducting cables have to be kept cold by a continuous flow of liquid nitrogen inside an insulated sheath along their length.

There’s a trade-off between the cost of refrigeration and the benefits of low resistance, and a small number of commercial firms seeking out niches where the sums come out in favor of superconductors.

Do the sums

“With superconductors, we have high current capability,” explains Ed Wylie of American Superconductor (AMSC). “The liquid nitrogen system is a cost. It's part of the losses, which are usually the same or slightly less than the normal electrical losses of traditional installations. Really, the whole thing comes down to economics.”

The cost of the liquid nitrogen itself is not a major issue, says Wylie, pointing out that it is made as a byproduct from industrial processes aiming to make liquid oxygen, so it is incredibly cheap. It’s also very safe to work with.

“It’s something like 78 percent of the air, it's non-combustible, and it's free,” says Wylie. “There’s an excess of nitrogen used in the food processing industry, so there's an infrastructure in place. With liquid nitrogen and appropriate cryostat equipment, the cable can do the job of superconductivity.”

He continues: “The cost of the cooling is part of a larger calculation to show the economics of superconductors. It’s project by project. People get excited because they're electrical engineers, but it’s not a universal panacea.”

It works, but only in niche applications: “It’s when all these things come together. Unless the stars align, it's always a near miss. It always comes down to economics or commercial reality, sadly, because I would love it to be everywhere.”

Long distance cables

One niche could be in some urban power distribution applications. As well as higher currents and lower losses, superconductors carry more dense current, so they can be made a lot smaller.

“The amount of power that you're trying to do in a space could be the key issue - if the client has limited space, a large amount of power to get from A to B, and a problem with heat,” says Wylie.

“If you have to take a large amount of power through a city and you have a duct, but no room for conventional cables which are too bulky, or a requirement not to heat the soil around it, that's the kind of reasons that make it work,” he says.

Other factors include the cost of real estate, difficulty in getting planning permission, or adding overhead cables. “Maybe you can’t build an overhead line in a downtown area, or you open the ducts up and there's no room for conventional cables. There might be physical room, but what about thermal room?”

The Korea Electric Power Corp. (KEPCO) did just this in a semi-commercial trial in 2019.

It needed more capacity in part of its 154kV network, which would normally be provided with a new 154kV cable, at a cost of around $3 million. Instead, it ran a 23kV superconducting cable along 1km of conduit between the secondary bus bars at two substations in Shingal and Heungdeok.

The superconducting cable project was projected to cost $12 million, but KEPCO spotted savings that could be made, including eliminating a 60MVA transformer, and using an existing conduit instead of digging a new cable tunnel.

AMSC built the earliest superconducting transmission project for the Long Island Power Authority (LIPA) grid in New York, The Holbrook Project feeds a Long Island electrical substation via superconducting cable in a 600m tunnel and was paid for by the United States Department of Energy in 2008.

The European Union is funding Best Paths, a project to develop a DC superconducting cable operating at 320kV and 10kA. The project is planning to use a two-cable system to create a connection with a capacity of 6.4GW, or roughly twice the output of the UK’s new Hinkley C nuclear power station.

“A conventional cable system capable of carrying this level of power would have a seven-meter-wide installation footprint,” the leader of the EU project, fiber company Nexans, said in a statement. “The superconductor cable packs the same power into a corridor just 0.8 meter wide.”

The project, with partners including CERN, will use a magnesium dibromide (MgBr2) superconductor.

Also in Europe, cable company NKT is leading SuperLink, a bid to build a 12km underground link in Munich, which would be the world’s longest superconducting cable. It is expected to have a power rating of 500MW, operate at 110kV, and connect two substations using existing ducts, kept cold by a cooling system with redundant backup coolers.

“We see superconducting power cables as a part of the future to ensure optimized access to clean energy in larger cities such as Munich,” says NKT’s CTO Anders Jensen, adding that such cables “make it possible to expand the power grid in critical areas without having to dig up half the city.”

Japan also tested the idea, building 500m and 1km cables in 2016 to take power from a solar plant in Ishikari City, Hokkaido. The experiment worked, proving that the cables did not deteriorate, and could be operated reliably.

That experiment has been followed up with designs for 50km and 100km cables, which could potentially find their way into large power grids.

The original Ishikari cables actually lead us to a data center. They terminated at the Sakura Internet Ishikari Data Center, an innovative DC distribution facility that operated in the 2010s.

Could superconductors find another niche inside such a building?

Into the data center

Data centers certainly have extreme demands for electrical distribution, with high power demands in small spaces. So in 2022, a team based in China and Cambridge, UK, designed a data center based on superconductors.

“In the future, it will be challenging to increase the power density for a 48V distribution system using copper cables/bus bars, particularly for a MW class data center, as the electric current in the low-voltage DC distribution system is fairly large,” say the authors, led by Xiaoyuan Chen of Sichuan Normal University and Byang Shen of Cambridge, in a distributing the power, in a paper published in Energy magazine.

“A 10MW class data center with ultra-dense high-efficiency energy distribution: Design and economic evaluation of superconducting DC bus bar networks.”

They continue: “As the copper cables/bus bars have a certain amount of resistance, huge currents lead to huge ohmic losses, which will indirectly produce a considerable amount of GHG emissions. In order to transport huge currents, the sizes of copper cables/bus bars need to be increased, which will induce other problems such as insufficient space for cable installation in data centers, the high costs of large amounts of cable materials, and the bulky system.”

They aren’t the first to look at high-temperature superconductors (HTS) in data centers. Google has a previously unreported patent in China (202011180110.2) for a theoretical superconducting data center.

But Chen and Shen’s group set out to design a 10MW data center built around HTS cables and connectors, and share their findings. We’ve reached out to the team, and haven’t heard back yet, but there is plenty to look at in the paper.

The group says: “Superconducting cables are well-suited for low-voltage high-current building sectors such as data centers,” citing the advantages: zero energy loss, ultra-high current-carrying capacity, and compact size.

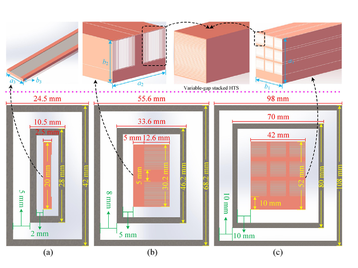

Their paper includes layout designs for HTS bus bars, and gives an economic analysis of the effects of switching to exotic superconducting bus bars.

Conventional bus bars have limited ability to carry large currents due to “huge ohmic loss,” said the researchers, while HTS DC bus bars could have “ultra-high current-carrying capacity and compact size.”

The superconducting bus bars would be expensive and are at this stage “conceptual,” the group reported, but the paper produced actual designs based on HTS DC bus bars and modeled the economics, trading off refrigeration costs against the benefits.

It concludes the design would pay for itself within about 17 years.

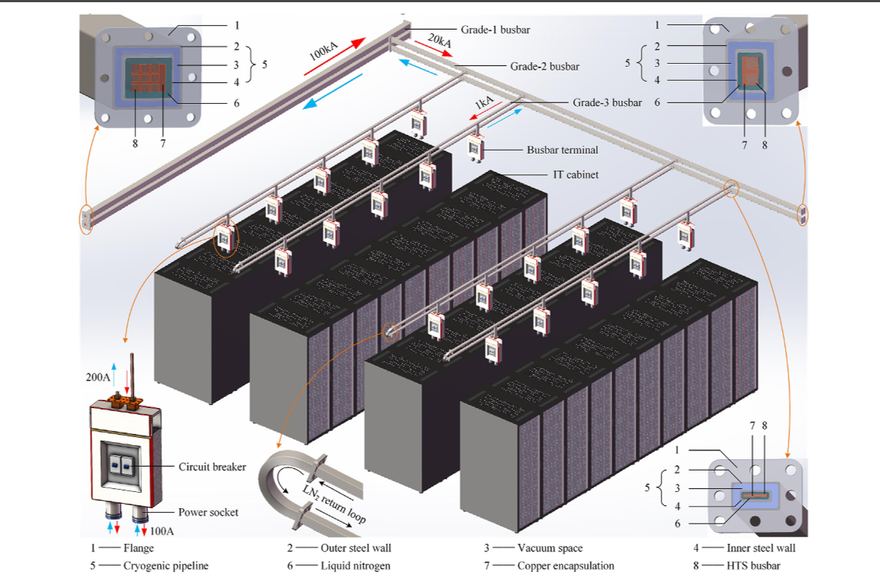

The bus bars are designed around 12mm superconducting tape from Sunam of South Korea, which can carry 960A of current. Three bus bar designs are provided, using multiple tapes to carry 10kA, 20kA, and 100kA of current. Each of these designs is surrounded by a cryogenic pipeline holding liquid nitrogen.

The design takes a basic 10kW cabinet, arranged in rows of 10, in a total space of 1,700 sqm (18,300 sq ft). The rows are grouped into blocks separated by hot aisles, cold aisles, “walk” aisles, and equipment transportation aisles.

Power comes from the distribution room on Grade 1 (100kA) bus bars and is passed to Grade 2 (20kA) bus bars which take it across the rows, and then to Grade 1 (10kA) bus bars extending above each row.

Attached to each row’s bus bar are five power adapters, each of which takes off power and delivers it through two power sockets to two racks.

The liquid nitrogen flows out along the branching network of bus bars, then back along a parallel return loop.

How much does it cost?

Unsurprisingly, the researchers found that HTS bus bars would be much more expensive than conventional bus bars, which can be made out of ordinary copper without the HTS systems’ cryogenic complexity.

The initial capital investment for superconducting bus bars in a 10MW data center depends on the voltage used. At 400V, the cost is around $5,000, rising to $22,700 at 50V, the report says. That’s a lot more than the cost of conventional copper bus bars, which come in at between $350 and $3,000.

However, the price difference could be made lower if a higher current system was used, and operational cost savings could tip the balance in favor of superconductors.

“Compared with the conventional copper bus bars, the HTS bus bars have the disadvantage of high capital investment cost,” say the researchers. “For example, for the 400V / 25kA scheme, the capital investment cost of HTS bus bars is about 15 times that of the conventional copper bus bars. Nevertheless, when the current level increases from 25kA to 100 kA, the capital investment cost of HTS bus bars decreases to eight times that of the copper bus bars.”

They report: “Although HTS bus bars have high capital investment costs in the initial development stage, they have significant advantages on the annual operating cost and cross-sectional area.”

The annual operating cost of a 400V/25kA HTS bus bar would be about 18.5 percent that of conventional bus bars, while the cross-sectional area would be 38.2 percent of a conventional system. Raise the current to 100kA, and HTS bus bars could be run for 10.9 percent of the conventional cost, and be about one-fifth of the cross-sectional area.

Reality check

This is an academic paper, and it’s pretty easy to predict the reaction of data center operators to the suggestion of adding cryogenic pipelines to their existing M&E infrastructure.

The liquid nitrogen would represent another engineering discipline required within the data center, meaning new skills would be needed. It would add to the complexity of the system.

It will also introduce another potential point of failure in a facility that must meet reliability demands. If the flow of liquid nitrogen stops, then power stops flowing, and the facility stops operating.

So it won’t happen unless there’s a really good additional benefit. Chen and Shen’s group suggest one possibility: Upgrades.

If power densities increase within a specific data center, more power has to be delivered to the racks. They point out: “The maximum allowable installation areas for bus bars cannot be enlarged, because the channel sizes of existing bus bars are fixed.” Replacing standard copper bus bars with an HTS system might allow enough extra current to be delivered to the equipment room, in the same space.

With no resistance, the bus bars won’t consume power by heating up, which the paper reckons would save power. They’d also not be a fire risk - they are artificially cooled, so there will be less risk of fire. Even if there is an interruption to the cooling, the conductors won’t suddenly heat up: the superconductor will quench, and all current will stop.

Wylie agrees that superconductors could find uses inside a data center: “If you have a major bus structure inside a building, that could utilize a superconductor. From a high-level description of the topology, we could determine whether a superconductor solution would work.”

And on a personal level, he’d be very pleased to see it happen. He joined AMSC eight years ago from the data center industry, and at the time, AMSC had done some work looking at the possibility of superconductors within facilities.

“It was one of the areas I asked about,” he told us. “They had looked at it briefly, and it didn’t come off.”

Maybe that’s about to change.