The huge demands placed on the data center today have left many organizations figuring out how to maximize their data center capacity and capabilities.

Meanwhile, the rise of Edge computing is fuelling conversations among data center operators about how best to serve more remote locations. Emerging from these challenges, the prefabricated (prefab) modular data center has seen significant growth in recent years.

A prefab data center is exactly how it sounds: individual modules or containers pre-fitted in a factory with equipment that can be stacked to create a larger data center where required. The modules can be shipped to a site pre-assembled and can be deployed much faster than traditional white space. They are designed to offer a flexible and efficient alternative to traditional data centers, with the aim of reducing deployment time, increasing scalability, and improving energy efficiency.

Indeed, such is the current momentum around prefab data centers, analysts expect the market to surpass $89 billion by 2030 - up from $21.9bn in 2021.

“In the last three, four, five years, it’s just gone crazy,” said Efficiency IT managing director, Nick Ewing. "For enterprise IT, for users in life sciences, oil and gas, automotive, defense, government, they’ve really begun to see real traction."

“It’s not for everybody. But the advantages really outweigh the disadvantages."

Prefab speed of deployment

One of the key selling points of prefab data centers is that they can be delivered much quicker than a traditional data center design and build project, and easily expanded as needed.

“Unlike traditional data center buildings or modular rooms, they can be expanded with ease, and offer customers many more options in terms of where they are located,” explained Chris Wellfair, projects director at Secure I.T. Environments.

“A containerized data center can contain all of the same HVAC equipment that a traditional DC would use, be just as secure, and handle very dense loads.”

Since the modules are manufactured in a production facility, the construction process is not hampered by inclement weather, resulting in faster completion times.

Wellfair noted that they can be built and fitted out entirely offsite, and delivered to a location where they only need to be plugged in.

“They also offer a great option for customers that may need to expand their data center in the future, as some are stackable,” he said. “Equally for sites that are limited on space, or have a building status that makes it impossible, or costly to build a data center room – they overcome all these issues. Some customers even use containerized data centers as a backup solution, that is ready to be shipped to a location when an emergency occurs at any time.”

Secure I.T. Environment’s own ModCel containerized data centers are available with flexible power, UPS systems, and cooling design, and can be expanded as more processing power is needed.

“They have been designed to meet the LPS 1175 security, fire, and integrity standards of any traditional data center build,” said Wellfair. “They are also Lloyds of London Certified, so can be safely shipped anywhere around the world. Units can even be deployed as Edge data centers or in isolated locations and remotely monitored, with the confidence that they are secure to theft and protected from the elements.”

Supply chain and sustainability benefits

Matt Holden, chief operating officer at Australia-based Leading Edge Data Centres (LEDC), said it isn’t just about the enhanced speed of deployment – the production process provides centralized quality control. He said the ability to manufacture centrally and then distribute to external sites means LEDC can deliver a factory-controlled product, specific to the site-specific conditions.

“The prefabricated building and its components and the prefabricated components can be manufactured, assembled, and system tested within a controlled factory environment meaning that the multi-disciplined teams can work together seamlessly and in a centralized location, creating the same output every time, ensuring the highest quality,” he explained.

That’s not the only benefit, said Holden, who added that LEDC manufacturing its own prefabricated data centers in Australia ensures sovereign capability is being developed, which is important to the company. Another potential advantage is that prefabbing can help ease issues firms might otherwise see around supply chains.

“Prefab can improve the impact of issues around supply chains by allowing some delays to be built into the schedule without impacting cost,” said Holden. “Because our data centers are manufactured in a facility, if deliveries are delayed, we can plug those delay gaps by moving tasks up in the schedule that would have to be fully sequential on a traditional data center build.”

Prefabricated modules can also help alleviate supply issues by using common building elements found in office buildings, homes, and other construction projects, said Tony Grayson, general manager of Compass Datacenters. They are also typically used in smaller quantities, which can further streamline the construction process.

“Another important benefit is that by prefabbing locally, transportation and installation costs can be significantly reduced. Additionally, local construction teams are often in closer communication with the appropriate AHJs (Authorities Having Jurisdiction) and can help avoid permitting problems,” he said.

The exec pointed to Compass Quantum’s design, which is designed to be manufactured in a production line, allows for large-scale deployments with rapid delivery. “Our solution is mass customized, allowing us to meet customer requirements while still keeping speed to market and costs lower. It can be rapidly installed on piers rather than large concrete pads, which has a number of benefits in terms of permitting and sustainability.” Sustainability, of course, is becoming an increasingly important consideration in the data center industry. “It is essential to incorporate sustainable practices at the Edge since prefabricated modules will be placed in residential areas and deployed in large, dispersed numbers,” said Grayson. “Retrofitting these modules later can be costly and difficult. By testing new technologies in prefabricated modules, we can explore more sustainable solutions and potentially lower the environmental impact of data centers. I believe this is an important step towards a more sustainable future.”

No pre-existing limitations

For Efficiency IT’s Ewing, the beauty of prefab data centers, aside from their speed of deployment, is their ability to be customized to the customer’s specific requirements.

“There’s a greater level of customization because you’re not constrained,” he said. “You don’t have four solid walls that you’ve got to work within because with modular, you can take two building blocks and put them together. So you can be flexible with what you’re doing.

“The key is its application and business specific. If a customer says this is what we’re looking for, this is what we need to achieve, whether it’s low density or really high density – we almost have complete freedom as long as technically it’s validated and it works.”

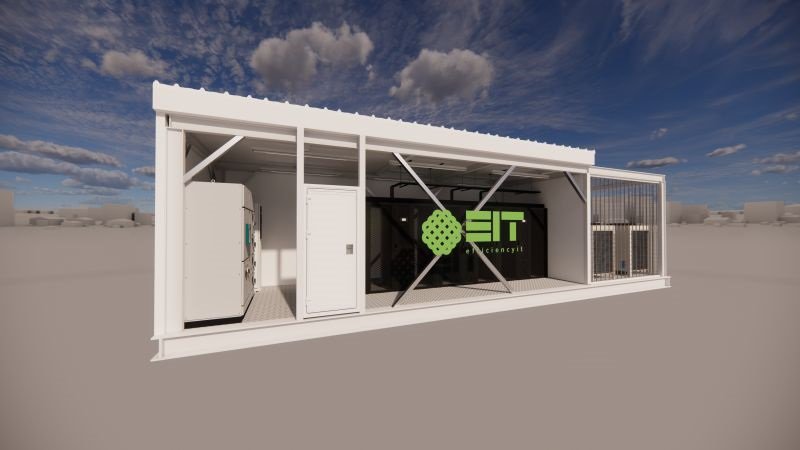

Efficiency IT recently launched ModularDC, a range of customizable, prefabricated data centers based on technology from Schneider Electric. Serving customers within government, defense, and other businesses-critical sectors – all of which typically need to react quickly to events – the data centers are deployable in as little as 12-16 weeks.

But as with anything, there is a tradeoff. Modular, prefabricated data centers won’t fit every customer's requirements. If you want to build in an existing room or building space, for example, then standing up a modular facility will be more expensive.

But where space is limited or costly, and there is space to put up a prefab in a warehouse or externally, then modular is a good choice. In many cases, the reason to opt for a prefab data center comes down to how quickly you can deploy, versus having to build from scratch. But also, customers are now realizing they no longer need to try to fit a round peg into a square hole when it comes to their data center requirements.

“The ability to customize a room inside a building is limited,” said Ewing. “The ability to customize something that sits outside of your building fabric, it’s far more available.

"That’s where we see a lot of the value – being able to tailor to the customer's needs. We are masters of our own destiny. We can design whatever the customer needs because we have no pre-existing limitations.”