In the fast-evolving landscape of data centers, a pivotal transformation has surged to the forefront – the criticality of waste heat recovery. As the data center market experiences exponential growth, driven by the soaring demands of High Performance Computing (HPC) to fuel AI advancements and power-hungry computing needs, the densities within these centers are escalating dramatically. This upsurge, while propelling technological innovation, is equally leading to an unprecedented generation of heat within these facilities.

The escalating volumes of heat emanating from data centers are no longer merely a consequence but a resource demanding astute utilization. This surplus of heat, with its potential for various applications, has incited a paradigm shift towards harnessing it for beneficial use. Waste heat recovery is transcending from being an option to an indispensable component in the operational framework of these centers.

Moreover, the global trajectory toward sustainability and regulatory compliance has significantly augmented the urgency for efficient heat recovery practices. Notably, countries like Germany have taken a pioneering stance by enacting stringent laws (Energy Efficiency Act) mandating waste heat recovery within data centers. These legislative measures underscore the imperative need to adopt sustainable practices, positioning waste heat recovery as a prerequisite to obtain authorizations.

In this article, we delve into the burgeoning importance of waste heat recovery within data centers, and how Engie and RED Engineering Design gather the necessary expertise to harness its potential.

The importance of data centers benefiting to the local communities

As data processing intensifies per rack, the dissipation of nearly all IT processing power as heat poses increasingly challenging issues. This has prompted IT equipment manufacturers to seek novel solutions as existing design concepts swiftly lose effectiveness.

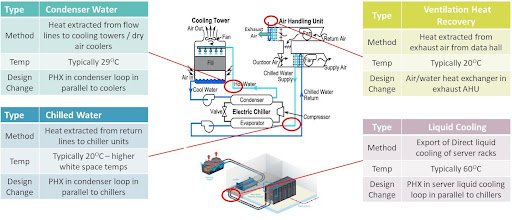

Regardless of whether a data center employs condenser water, chilled water, or mass air flow for heat rejection, the total amount of heat rejected remains constant. However, variations arise in the temperature at which this heat can be efficiently harvested for supplying district heating schemes or any direct consumers, along with the energy and water consumption needed for heat rejection.

Simultaneously, the emergence of urban district heating and cooling networks has gained momentum as a primary avenue toward achieving low-cost, low-carbon heating or cooling provisions across residential, commercial, and industrial sectors.

The evolution in heat generation plants, heat pump technologies, pipework materials, and automated control systems has seen a transition from the old steam-based district heating systems to high-pressure, high-temperature hot water networks, and more recently to low-temperature hot water systems aligning their operational temperatures close to building heating and hot water systems.

The latest (5th) generation of district heating networks operate at much lower temperatures and rely on large volumes of low-grade heat, with the principal grid carrying a low temperature flow to active and distributed substations which upgrade the temperature to the required level using heat pump technologies.

These systems are better able to capitalize on heat being rejected from the data center, as well as below-ground thermal storage and renewable thermal energy generation. The end result is a network which has a significantly lower carbon emission footprint for the overall system, which is able to provide low/stable cost, reliable heat to consumers.

There is therefore an evident synergy between the large amounts of low-grade waste heat being rejected from data centers and the new low-temperature district heating systems being increasingly installed in urban areas and industrial sites.

A palpable synergy emerges between the copious amounts of low-grade waste heat expelled from data centers and the rising prevalence of low-temperature district heating systems in urban and industrial locales.

Furthermore, direct consumers in close proximity stand to benefit from the waste heat generated by data centers. Buildings with consistent high energy demands align well with the steady waste heat profile of typical data centers throughout the year.

Climate considerations heavily influence the energy demand for space heating, while facilities like kitchens, swimming pools, and greenhouses with sustained heat demands can leverage available waste heat. Industries requiring substantial heat, often operating continuously, also stand as prime candidates for utilizing this surplus heat, potentially storing it when feasible.

How can waste heat be recovered?

Assuming the IT load remains constant all year-round, the fluctuations in energy usage across seasons, reflecting the difference between maximum and minimum PUE (Power Usage Effectiveness), will primarily stem from varying cooling demands influenced by external weather conditions. As a result, the anticipated heat rejection profile will establish a high baseline with relatively minor fluctuations, contingent on the cooling system implemented.

The nature of the cooling system within a data center dictates the potential extraction of waste heat. For water-cooled chillers, waste heat can be reclaimed from the condenser water loop; for air-cooled chillers, it can be recovered from the chilled water loop; or, in mass air cooling systems, waste heat can be accessed via a heat exchanger integrated into the exhaust ventilation system.

Amidst the rapid evolution of AI and, in general, the escalating demand for High Performance Computing, a new frontier in waste heat recovery emerges. As liquid-cooled server racks or immersion cooling systems make their foray into the market, they bring with them a potential of higher-grade waste heat.

While the predominant hardware for HPC servers relies on air cooling, the advent of liquid cooling technologies signifies a pivotal shift in efficiently expelling heat from CPUs and GPUs. This streamlines the servers’ form factor by shortening the airflow path, thus facilitating denser IT configurations, catering to ever-increasing computing demands.

In a notable development early 2023, Nvidia launched direct-to-chip (D2C) liquid-cooled versions of their renowned GPUs, specifically targeting the burgeoning AI market. Furthermore, immersion cooling is gradually making its way into select scenarios. This surge in liquid cooling technologies heralds the long-awaited adoption to accommodate rack densities ranging from 25kW up to 150kW per cabinet.

Based on this, the temperature of the waste heat reclaimable in the return water loop spans from 40 to 60°C. This temperature range not only enhances the efficiency of heat pump systems but also broadens the scope to serve a larger consumer base compared to lower-grade waste heat scenarios.

Not a utopia

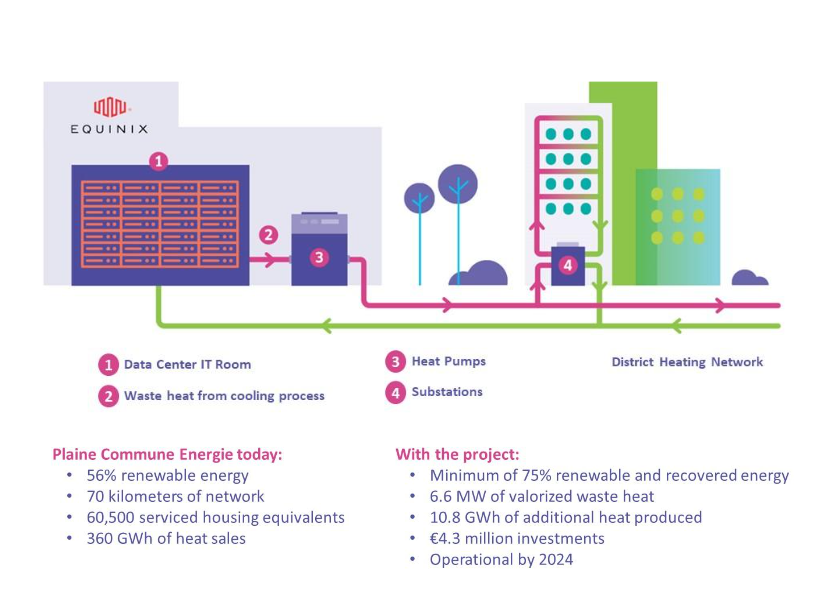

Waste heat recovery initiatives already exist. A notable example involves Equinix's data center, slated to connect with the Plaine Commune Energie heating network, a 100 percent subsidiary of Engie Solutions. This collaboration aims to infuse the heating network with a greener energy mix, targeting a minimum of 75 percent renewable and recovered energy.

Plaine Commune Energie stands as the second largest heating network within the Paris area, stretching across a 70-kilometer expanse. Catering to five metropolitan cities, including Saint-Denis, this network services approximately 60,500 households and extends its reach to the new Olympic aquatic center in Saint-Denis.

The proposed waste heat recovery plan entails capturing heat at 28°C, harnessing 6.6 MW generated from the data center's cooling process through the utilization of heat pumps. This initiative is expected to yield an additional 10,800 MWh of heat, ensuring sustained output over a minimum duration of 15 years. Such collaborations exemplify concerted efforts to channel waste heat into sustainable energy solutions, promising enduring benefits for local communities and infrastructure.

An efficient waste heat recovery project needs District Heating and Cooling networks expertise

With an extensive track record spanning the globe, Engie stands as a seasoned authority in the realm of financing, designing, and operating district heating and cooling systems. Teaming up with RED Engineering Design for critical facility expertise, Engie and RED Engineering Design emerge as the ideal partner to efficiently harness and distribute waste heat to local consumers, leveraging years of experience.

As a matter of fact, Engie has already performed diverse waste heat recovery projects in various industries, ranging from tire manufacturing to food processing.

While the export of waste heat operates as a distinct project, it runs in parallel with the data center's development. Engie and RED Engineering Design have meticulously developed in-house tools, empowering their expertise and streamlining project development.

Identifying potential heat consumers before planning the waste heat export scheme is pivotal, as their involvement will solely underpin the system's income and profitability. This necessitates a comprehensive heat mapping exercise, utilizing such in-house tools to identify neighborhoods and industrial zones where heat distribution promises both beneficial and economically viable outcomes, utilizing heating demand profiles across the year.

Engie's modeling tools will provide daily projected profiles for each identified heat consumer throughout the year. By aggregating these profiles for each consumer on the network, they're calibrated against the heat rejection profile from the data center to optimize energy harvesting. Simultaneously, RED Engineering Design engages in modeling the heat export profile from the data center.

Prior to committing any investment, Engie conducts meticulous techno-economic modeling to define the risks and benefits of the waste heat recovery scheme. These ventures can necessitate substantial investments, considering the expenses incurred in below-ground network installations, constructing new energy centers for streamlined waste heat export, and modifications to both data center systems and consumer heat take-off points.

Crucially, this modeling assesses the distance between data centers and consumers, calculating the size of the heating network and thus the overall capital cost, which in turn may affect the location of the data center in terms of mitigating overall costs.

Carrying all these processes enables them to build long-term partnerships with key stakeholders such as local authorities and industrial clients. These collaborations, featuring well-defined technical and contractual interfaces, effectively mitigate operational and financial risks for data center operators.

Conclusion

In the pursuit of net-zero carbon footprints, data centers’ waste heat recovery schemes emerge as a linchpin in community sustainability strategies. Engie and RED Engineering Design stand at the forefront to assist data center operators in leveraging this untapped energy resource through comprehensive support encompassing financing, design, installation, and operation of the involved energy equipment.

As the landscape witnesses a burgeoning influx of High Performance Computing data centers, marked by the adoption of increasingly efficient cooling systems, the consequential rise in output temperatures intensifies the relevance of reclaiming waste heat. The evolution of district heating networks, engineered to function efficiently at lower temperature thresholds, heralds a pivotal juncture between those assets.

More from Engie and RED Engineering Design

-

DCD>Talks emerging power pressures with Patty Solberg, Engie

DCD's Dan Loosemore talks with Engie's Patty Solberg about emerging power pressures.

-

Sponsored The embodied carbon challenge for truly net-zero data centers

Calculate, compare, contrast. The three C’s to achieving embodied carbon reduction throughout the entire data center lifecycle

-

Sponsored Is on-site power and cooling production a viable solution to decarbonize your data center?

A total cost of ownership approach