The simultaneous increase in data processing, transmission, storage and the climate change targets being imposed at global, national and corporate level are challenging the industry to think of new ways of how we provide power and water to data centers.

Hitting these targets will involve a number of different concepts and technologies and will need to be progressively introduced into both new and existing developments as a roadmap to carbon neutrality.

The growth in the data center market continues to accelerate as digital technology has become democratized and central to all aspects of global life, driven by multiple factors such as cloud data storage and processing, data streaming to individuals’ devices, the Internet of Things, Big Data and the rise of Artificial Intelligence.

This trend will have a direct effect on the energy required to service the data centers used directly for the IT process as well as in the electrical distribution, switchgear, ventilation, cooling, and lighting.

Communities across the globe are becoming more aware of the environmental impact data centers have on their cities. In February 2020, EU commission noted that data centers and telecoms have significant environmental footprints, and they should become climate neutral by 2030. Large IT companies such as AWS, Facebook and Google have taken the lead in recovering waste heat from their data centers to contribute to the economy and well-being of communities.

Furthermore, in countries where heating is required at certain times of the year, the increasing cost of energy linked to other rises in world commodity prices is having a huge impact on the population. This means that an increasing proportion of society is being forced into a “Heat or Eat” scenario where keeping warm in winter is more and more challenging and the energy costs related to manufacturing are driving costs up even further in the industrial sector.

A new approach: Data centers benefitting the local community

As data processing and handling becomes denser per rack, and as nearly all the IT processing power is dissipated as heat, the challenges associated with the rejection of heat becomes even more problematic and has led IT equipment manufacturers to look at new solutions due to present design concepts quickly becoming ineffective.

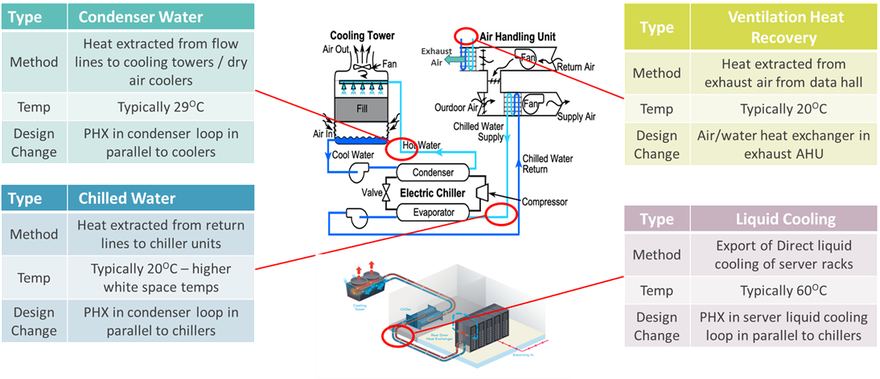

The heat rejected from a data center will be the same whether it uses condenser water, chilled water, or mass air flow as the means of heat rejection. The difference will be in the temperature at which the heat can effectively be harvested to supply to the district heating scheme, and the electrical energy and water consumption required to reject that heat.

In parallel, the development of new urban district heating and cooling schemes is now ramping up quickly as one of the main pillars to achieving a low carbon/low-cost environment for residential, commercial, and industrial applications.

With the improvement in the efficiency of heat generation plants, pump technology and pipework materials, as well as the increased effectiveness of automatic control systems, steam-based district heating systems have been largely replaced initially by high pressure/high temperature hot water systems, and latterly by low temperature hot water systems which have flow temperatures slightly above the operating temperatures of building heating and hot water systems.

The latest (5G) version of district heating systems operate at much lower temperatures and rely on large volumes of low-grade heat, being distributed to points of use where temperatures are uplifted using heat pump technology.

These systems better able to capitalize on heat being rejected from cooling systems, as well as below-ground thermal storage and renewable thermal energy generation. The end result is a network which has a significantly lower carbon emission footprint for the overall system, which is able to provide low/stable cost, reliable heat to consumers.

There is therefore an evident synergy between the large amounts of low-grade waste heat being rejected from data centers and the new low-temperature district heating systems being increasingly installed in urban areas and industrial sites.

Through its longstanding expertise in the financing, design, construction and operation of district heating and cooling systems all over the world, alongside the technical support of Red, Engie is the right partner to effectively harness this waste heat and efficiently distribute it to local consumers. This expertise will be key to assessing the feasibility of this practice and optimizing the design to give the best possible results in terms of low-cost and low-carbon heat for local communities.

How it works

Nearly all the power input into IT processes is output as heat, with any additional power required for the site due to cooling, ventilation, lighting, electrical equipment losses, distribution losses and welfare or staff activities. The PUE (Power Usage Effectiveness) of a facility defines the ratio between overall power into the site and the power used for IT processes.

Assuming the IT load remains constant throughout the year, then the variations in energy consumption across the year, representing the difference between maximum and minimum PUE, will be mostly due to varying cooling energy loads due to variations in external weather conditions. The expected heat rejection profile will therefore have a high baseline, with relatively small variations and will very much depend on the type of cooling system in place.

Depending on the type of cooling system in the data center, waste heat can be extracted from the condenser water loop for water cooled chillers, from the chilled water loop in the case of air-cooled chillers, or from a heat exchanger in the exhaust ventilation system for mass air cooling systems. In the future, higher grade waste heat will become available as the installation of liquid cooled server racks start to come to market.

The advent of liquid cooled servers will result in higher temperatures being rejected to the heat networks, meaning consumers can achieve better efficiencies from their heat pumps, therefore providing even lower cost, lower carbon energy.

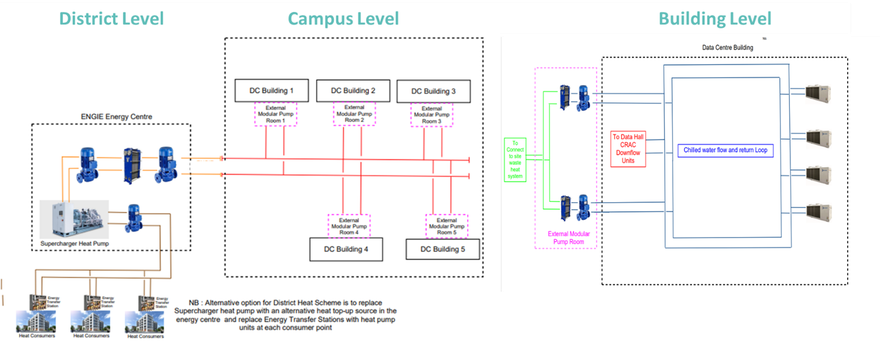

The district heating scheme components will typically comprise of:

- A heat interface with the heat rejection circuit in the data center.

- An energy center (or multiple energy centers) which house the heat generation plant (through combustion of other means), the distribution system pumps, the water treatment plant and the pressurisation system.

- Thermal storage which can be integrated with the energy center or external, either below or above ground.

- Hot water flow and return pipework distribution system usually located below-ground.

- Heat interface units in individual properties or in larger buildings’ plant rooms which replace the heating boiler plants.

- A centralized control system to monitor, log and control the operation of the whole scheme to provide early detection of faults and to optimize the operational performance of the system.

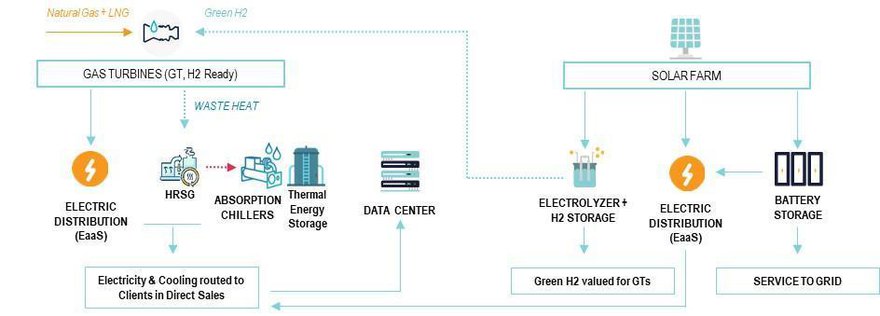

- If a combined heat and power (CHP) unit is incorporated, the energy center will also include a power generation section, used to power a local private wire microgrid.

Additionally, machine learning and/or Artificial Intelligence technology, will be able to calculate the optimum operating temperatures of the district heating network at different external temperatures across the year by calculating the highest possible Coefficient of Performance (COP) of the consumer heat pumps, versus additional energy required at the energy center, leading to the maximum energy efficiency of the whole system at all times.

Design considerations

It is key that the operating parameters of the data center cooling systems are respected when calculating design temperatures, pressures, and flow rates for the distribution system ‒ including the energy center. If during operation, these parameters exceed the design thresholds, then the control system will isolate the data center heat rejection circuits so that they operate in stand-alone mode.

At the points of consumption connected to the waste heat distribution loop, heat pumps will normally be required to uplift the temperature to the levels usually required in a building or in an industrial process. The district heating developer will supply and install a plate heat exchanger at each point of consumption, be that a plant room or property, such that the district heating circuit is hydraulically isolated from the consumers’ heating systems.

Once again, the design of the system will need to take into account frost protection of the pipework and plant in colder climates, which will usually involve the use of glycol anti-freeze. Although this method will lead to higher operating and maintenance costs, it is the most secure way of avoiding potentially catastrophic frost damage when parts of the system are off-line with low or no water circulation.

Buildings with high baseloads will obviously better match the waste heat rejection profile of a typical data center, which is relatively constant all year round. Evidently the local climate will play a large part in the overall energy demand for space heating, whereas constant heat demand loads such as kitchens, swimming pools, fitness centers and elderly care home facilities will be able to capitalize on the waste heat availability.

Generally, the best heat takers are those from the process sector which needs large quantities of heat, some of which can be stored when beneficial, although in many cases these environments operate on a 24/7 basis. This is particularly the case during continuous as opposed to batch production processes and, at times, production alone can consume all the waste heat available.

The peaks and troughs over the course of a 24-hour period for each type of building can be mitigated to a certain extent using thermal storage, which can be charged during periods of low heat demand and discharged during periods of high demand. Optimum storage volume can be calculated by carrying out aggregated heat demand profile simulations for all buildings on the district heating loop during the heating season, and checking the effect of different simulated water volumes on overall instantaneous demand.

Financial considerations

The heat export network is a separate but parallel project to the development of the data center which Engie, supported by Red, is well positioned to design, construct and operate as a long-term partnership with stakeholders such as local authorities and industrial clients, and with a clear technical and contractual interface to remove any operational or financial risk from the data center operators.

It is essential that potential heat consumers are identified before the waste heat export scheme is planned, as these will represent the sole source of income for the system and the profitability of the scheme will be maximized when the waste heat produced matches the demand as closely as possible. Just as importantly, the more of the waste heat that is used, the larger the potential for consumers to significantly reduce their Carbon and NOx emissions.

Engie’s modelling tools will provide daily projected profiles for each of the identified heat consumers for each day of the year, aggregate these for all consumers on the network and compare these to the heat rejection profiles from the data center(s) to optimize the quantity of energy being harvested and therefore the impact on carbon emissions.

Heat mapping will also be performed via in-house tools. It is the analysis and display of heat demand areas using a detailed geographical map which is intended to help identify neighbourhoods and industrial sites where heat distribution is most likely to be beneficial and economically viable, utilizing heating demand profiles across the year.

Engie will then carry out an accurate techno-economic modelling before any investment is considered, in order to define the risks and benefits of any waste heat recovery scheme, as these investments are likely to be considerable in light of the costs of installing a below-ground network, constructing a new energy center and modifications to the systems in the data centers as well as in each of the consumers’ heat take-off points.

Part of this modelling will be to assess the distance between the data center and the consumers, calculating the size of the heat network and thus the overall capital cost, which in turn may affect the location of the data center in terms of mitigating overall costs.

As a minimum, the following information will be required to provide an investment grade assessment for the viability of the scheme:

- Heat rejection profiles for the data center between the start of the project and at full capacity.

- Type of data center cooling systems.

- Heat mapping results of potential consumers, complete with projected demand profiles and likelihood of connection.

- Present and projected future costs of gas, oil, and electricity.

- National and local government incentives, levies, and tariffs.

Financially viable projects would usually be expected to have an annual rate of return (IRR) of between 12 and 15 percent and have a positive NPV (net present value) which indicates that the investment would be better than a more orthodox investment, for instance, a financial institution. Any risks need to be identified and mitigated by including an extensive sensitivity analysis as part of the financial assessment.

Apart from the obvious benefits of being able to reuse the waste heat off-site ‒ including the financial gains from selling the heat with the potential for government incentives ‒ the running costs of the data center itself will be reduced as a result of the air cooler/cooling tower fans operating at a lower speed, or better still, not operating at all when sufficient heat is being rejected through the district heating scheme.

Conclusion

The huge increase in the roll-out of data centers to serve the requirements of the modern world means that the vast amounts of waste heat being rejected by IT processes is only set to become greater as time passes. In effect, nearly all the electrical power being consumed by the buildings is being sent into atmosphere as thermal energy which no one is benefitting from.

This is obviously unsustainable and the increasing appetite from the industry to decarbonize will need to be tackled on a number of fronts, including supplying green electrical power to processes, reducing power and water demand, optimizing energy storage, and harvesting the waste heat for export.

Decentralized heat schemes are being recognized globally as one of the essential tools for sites and communities to reach zero carbon in line with local and national government as well as private sector targets.

Additionally, effectively designed and operated district energy schemes are increasingly being seen as a means to deliver heating and/or cooling at a lower price to customers compared to conventional systems, whilst at the same time reducing stress on national utilities networks.

Engie’s experience in funding, building and operating these systems together with Red’s expertise in providing effective technical support ensures that they run at the lowest possible cost with the smallest carbon emissions.

The additional element of harvesting waste heat from industrial processes is now also recognized as being one of the most effective ways of delivering low energy costs and zero carbon systems. As a result, the construction of data centers as one of these industrial processes, will often require a study to be carried out to assess the viability of exporting heat to nearby consumers as part of the planning application.

The energy consumed, CO2 emissions and running costs of an overall waste heat district heating system ‒ including the heating network, energy center and consumer heat pumps ‒ will usually be considerably less than the total energy consumed by building users employing other traditional heating technologies such as gas, oil or air source electric heat pumps. This is especially true in colder climates and/or where heat is required for services or processes throughout the year. The strategy also allows for complete disconnection from the gas distribution network and therefore reduces the reliance in fossil fuels.

The success of waste heat systems is dependent on the accurate collation of data on potential existing and future heat consumers located reasonably close to the data center and comparing this with the estimated waste heat availability.

This combined with an accurate and complete financial analysis of the heat balance across the year, together with an estimation of capital and operating costs is essential to establish how viable the projects are from an economic point of view.

Data centers increasingly need to be seen as a clear benefit to nearby communities by becoming a local source of zero carbon heat at a much lower cost to consumers without the volatility of market rates compared to heat produced from fossil fuels. Engie’s position in the energy market is ideal for combining its knowledge of the industry and experience in investing in long-term zero carbon projects together with the Red’s extensive experience in the design of data center cooling systems.

Future articles will deep-dive into this waste heat export topic, providing technical-economic insights on how data centers are able to provide low and stable cost energy, and on the feasibility approach of the connection of a data center to a district heating network.

For more information and to contact Engie, please visit the Engie website.

More from Engie and Red Engineering

-

Sponsored Microgrids and data centers: How to increase high availability while achieving decarbonization objectives

The N+K microgrid can provide an effective alternative to the traditional N+1 or 2N resiliency. Here’s how it works

-

Sponsored Actions over (buzz)words

What does it actually mean to be green?

-

Sponsored Will decarbonization impact future data center design?

A closer look at the prosumer approach, with Eric Lamendour of Engie