Industrial rack-mounted uninterruptible power supplies (UPSs) are used in data centers or telecom central offices to provide backup power for servers and switching equipment in the event of failure. Historically, these UPS’s have relied on Lead Acid as the predominant battery type. With the introduction of the Open Compute Project (OCP) initiative and hyperscale data centers, Lithium-ion batteries are gaining market share over the incumbent Lead Acid battery technology.

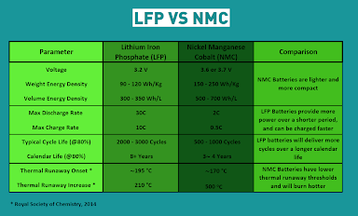

This article presents some of the thermal considerations and trade-offs when selecting a Lithium-ion UPS system to complement your data center equipment. There are two available chemistry options Lithium Iron Phosphate (LFP) and Lithium Nickel Manganese Cobalt Oxide (NMC). Operators need to consider expected discharge time, active versus passive cooling, options for scalability, and the expected lifetime of the batteries.

Two practical Lithium chemistries for UPSs

For typical UPS applications, there are two popular Lithium-ion chemistry variants offered by UPS vendors. Lithium Nickel Manganese Cobalt Oxide (NMC) is the most common Lithium chemistry in the world, as it is predominantly used in notebooks and cell phones for example. Lithium Iron Phosphate (LFP) is less common in consumer applications but is used in high cycle life or high-power applications such as power drills or industrial electric vehicles (buses, forklifts). While both chemistries are based on Lithium-Ion exchange, they have some significantly different performance characteristics.

As detailed in Image 1, NMC chemistry has a higher weight and volume energy/density ratio than the competing LFP chemistry. Additionally, NMC chemistry has a lower cost/Watt-Hour than LFP. As a result, the higher energy density and lower cost makes NMC the optimal chemistry for most lower power consumer applications. This means that, given a certain volumetric space allowance for the UPS, an NMC-based UPS will deliver more run-time than the comparably sized LFP-based UPS.

Three main dimensions affect the longevity of a Lithium-ion battery – number of cycles, the length of time in service, and the average temperature of the cell. Industry norms measure the effectiveness of a battery by comparing the actual capacity relative to the original capacity of a fresh battery. LFP Batteries deliver at least 2000 – 3000 full charge/discharge cycles before reaching 80 percent of their original capacity. Typical NMC batteries deliver 500 – 1000 full charge/discharge cycles before reaching 80 percent of their original capacity. This means that LFP batteries provide two-to-three times more cycle life than typical NMC batteries. While the calendar life of an NMC battery is three-to-four years, the calendar life for a LFP battery typically exceeds eight years. The largest factor in the life of a Lithium-Ion battery is the average temperature of the cell, closely followed by the depth of discharge.

Safety

LFP Batteries have an intrinsically safer cathode material than NMC batteries and do not decompose at higher temperatures. In effect, LFP batteries provide the best thermal and chemical stability, which results in superior safety over NMC batteries. As detailed in Image 1, a LFP battery will only enter a thermal runaway condition at 195 Celsius and release minimal energy during thermal runaway. A typical NMC battery can enter thermal runaway condition as low as 170 Celsius and will release more energy and burn at a much hotter temperature. All Li-ion batteries are safe, but LFP is one of the safest Lithium-ion battery chemistry available.

Temperature and discharge

In general, there are two typical use models for UPS solutions. The first application is when the data center operator plans to use the UPS for a 5-to-10-minute interval, specifically, the interim period from power loss until the back-up generator is started. In this scenario, the UPS is sized to deliver all available energy at a very high rate. The second application is when the data center operator plans to use the UPS for a one to eight hour discharge and wishes to avoid starting the backup generator until it is absolutely required. In this application, the UPS is the primary source of power for a much longer period.

LFP has a very low internal impedance and can be discharged at very high rates without generating much heat. NMC has an internal impedance about 10x higher than LFP and will generate more heat internally when discharged at the same rate of a comparable LFP cell. As an example, a 48 Volt 50 Amp-Hr NMC battery (2400 Watt-Hr) can deliver around 50-100 Amps, while a similar-sized LFP battery can deliver around 500-1000 Amps. The power delivery is a critical factor in the UPS configuration. To deliver a specific amperage profile, multiple NMC batteries may need to be connected in parallel to reach the needed Amps, while a single LFP battery may deliver the required Amps. Given a specific space constraint, this means that a NMC battery is more appropriate for applications that can tolerate lower current delivery over a longer discharge period (i.e., 50 Amps over one hour), while LFP can also accommodate a higher current delivery over a shorter discharge period (i.e., 300 Amps over 10 minutes). The expectation for back-up runtime is a critical factor in selecting the battery chemistry.

Passive or active cooling

If you survey the market of rack-mounted UPSs, you will notice that there is a variety of options for thermal management, ranging from passive cooling (no fans) to active cooling (continuously running fans) to dynamic active cooling (variable rate fans driven by internal battery temperature). The third dimension that affects the longevity of Lithium-ion batteries is the ambient temperature. Lithium-ion batteries can safely operate between -20 and +60 Celsius, but the optimal temperature range to maximize the battery life is between 10 and 30 Celsius. High current discharges will create internal heating within the cell, but a stable temperature environment maximizes the battery’s life.

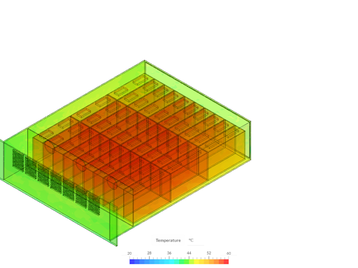

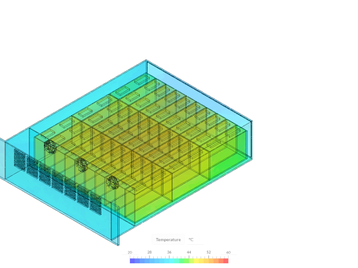

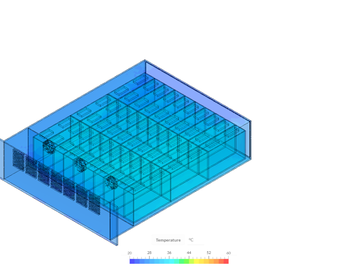

Images 2, 3 and 4 demonstrate the impact of active cooling with fans on a UPS battery. The thermal images are modeling a 48 Volt 100 Amp-Hr NMC battery (4800 Watt-Hr), and they show the surface temperature of the Lithium-ion cells contained with the UPS. In Image 2, the UPS is continuously discharging at 150 Amps (1.5C rate) without any active cooling. The peak temperature of the cells is around 60 C, which is close to the safety cut-off limit imposed by the UPS electronics. Then, in Image 3, active cooling is applied through the UPS enclosure while the battery is delivering 150 Amps, and the peak temperature of the cells drops to around 50 C, noticeably cooler and safely below the cut-off limit. To demonstrate the effects of discharge rates and current delivery on the UPS, Image 4 shows the UPS discharging at 50 Amps (0.5 C rate) with active cooling. The cells are noticeably cooler than the UPS delivering 150 Amps with active cooling. Note that based on the chemical composition and higher impedance of NMC cells, they will generate more heat when discharging compared to LFP cells. Given that heat abatement is a critical issue within data centers, the chemical composition of LFP cells does give it an advantage in climate-controlled environments.

Active cooling advantage

Typically adding more complexity to a product by introducing fans and thermal regulation can be seen as a disadvantage, but there are some advantages. In applications that do not have climate control the cabinet temperature can range from very cold and dry to extremely warm and humid. Batteries are very large and have a large thermal mass. In a passively cooled battery, the center of the battery may heat faster than the external cells during a discharge event from internal heating, thus creating a hot spot and limiting the amount of discharge current available. This will also prematurely age the cells in the center of the pack. An Actively cooled battery can better remove heat from the cells during a discharge or charge event. An actively cooled battery can also support higher charge and discharge currents than an equivalent passively cooled battery.

This can also present a challenge for condensation. In the morning, warm moist air from the environment may enter the cabinet and contact the batteries, that have been cooling all night. This humid air may condense water onto the sensitive electronics inside the battery due to the temperature difference. Condensation on electronics may alter the functionality or damage the components of the battery over time. Active cooling, where air is passed over the electronics and cells, also has the advantage of keeping the electronics temperature the same as the air temperature, thus preventing condensation.

In summary, there are many rack-mount UPS solutions available on the market. Before selecting a manufacturer or model, you should perform a power study on your data center equipment to assess the power needed to sustain operations during a power loss, runtime required, determine the type of environment you will be operating in and determine how heat may play a factor in your decision. Armed with this data, you can assess critical features like the Lithium-ion battery chemistry, passive and active cooling features, and chemistry traits offered by available solutions. Once you have factored these features into your selection criteria, the subsequent list of viable manufacturers and UPS models will ensure the selected UPS provides the needed power during outages.

Author’s Bio:

Jeffrey VanZwol is the Chief Marketing Officer with Green Cubes Technology. Jeffrey’s range of experience includes engineered power solutions for Original Equipment Manufacturers (OEM) and Fortune 1000 enterprise customers. Prior to joining Green Cubes, Jeffrey was a senior Marketing executive at Inventus Power and Micro Power Electronics, as well as Alcatel (Newbridge Networks division) and ADC Telecom.

Company URL: