In the fast-evolving landscape of data centers, the industry is facing new challenges in its development. While more and more areas start to experience power shortages, data center operators are looking for fast interconnect solutions to support their rapid growth, driven by the soaring demands of High Performance Computing (HPC) to fuel AI advancements and power-hungry computing needs.

The availability of suitable land and local acceptance are also becoming key elements in supporting industry expansion. This is something the industry needs to cope with, while respecting its strong commitment to its net-zero transition in terms of carbon emissions and water usage.

As a result, we now need to look towards a new approach in designing and operating energy infrastructures for data centers, ranging from microgrids to campus scale utilities, that prioritize the use of decentralized and decarbonated generation. This will help to guarantee the resilience of the utilities serving the data center and futureproof schemes that allow for the incorporation of zero-carbon generation, as new technologies and fuels come to market.

Engie has committed significant resources to researching and bringing new technologies to market for the production, distribution and storage of new green fuels, allowing the company to be at the forefront of the zero-carbon fuel chain.

RED Engineering Design, 100 percent part of Engie, has worked in conjunction with Engie to establish a new, flexible and future-proofed design for data center energy infrastructure, which will update power and cooling generation systems to accept these new fuels as they come to market, transforming them into primary drivers for the zero-carbon transition.

This article will dive into the future fuels that are coming or will come to the market, how to use them for net-zero carbon power and cooling generation, and how Engie and RED Engineering Design can support you to implement this new energy approach.

On-site power and cooling generation as a solution

If a data center has on-site power and cooling generation (“microgrid”) capabilities that can be operated continuously, running on an affordable mix of fuels with a very low emissions footprint, then it may very well be used as a primary source of power.

Designed with capacity, redundancy and concurrent maintainability to ensure that sufficient capacity to cover the data center’s maximum load is always available, such a plant is able to provide a power supply without interruptions, even during the maintenance of individual equipment.

This approach reverses the traditional way of operating the data center energy source, where the on-site power plant becomes the primary source of electricity, and where the electricity grid is not required anymore or can act as an alternative source of electricity.

Engie and RED Engineering Design propose different energy architectures depending on local constraints and project challenges. Mix-fuel gas engines and gas turbines are usually part of the equation.

The flexibility in the quantity of gas turbines installed on-site enables operators to align generation capacity with the data center IT load ramp-up, avoiding undersizing – as well as oversizing – of the on-site power plant and systems.

In the case of rapid expansion of the IT load, modular on-site generation capacity is key to quickly ensuring a sufficient power supply, allowing the data center to become independent of the public grid power supply and avoiding overloading of the network.

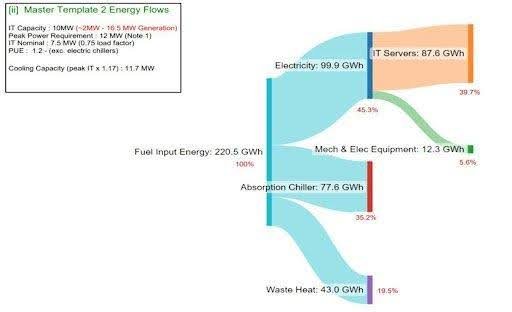

When it comes to lowering the environmental impact of a data center, overall energy and water efficiency are key topics to address. A way to make the microgrid operate at high efficiency is through the use of trigeneration.

Mix-fuel gas turbines provide the required power to the data center, with exhaust fumes at a temperature of around 600°C produced as a by-product. Steam can be supplied via waste heat boilers from the cogeneration sets to two-stage absorption chillers, which provide a highly resilient and highly efficient source of chilled water for data center cooling. In turn, this also drastically reduces the amount of water needed in the cooling process.

In the future, both gas engine and gas turbine generators will be able to accept an increasing blend of green fuels such as biogas with the ultimate aim of running on 100 percent green fuels as supply chains develop.

This new approach to waste energy has turned out to be far more efficient than traditional designs which use primary power from the electricity grid backed up by additional on-site diesel generators, drastically reducing net energy losses to the whole supply chain.

How to know what fuels can be used, for what, when and where

For zero-carbon on-site generation to move forward, the choice of fuel is crucial. Today, generation equipment such as gas turbines and engines are flexible in accepting different fuels, but the supply chains of the new green fuels are still developing. For a data center to run on a 24/7 basis without any interruption, it is critical to choose the fuel that makes the most sense, depending on the data center’s location and environment.

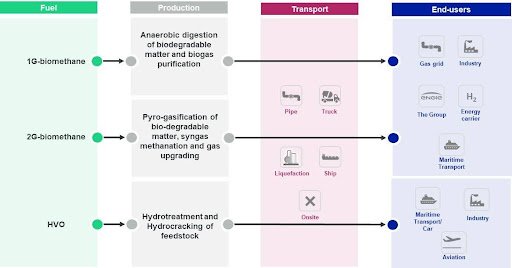

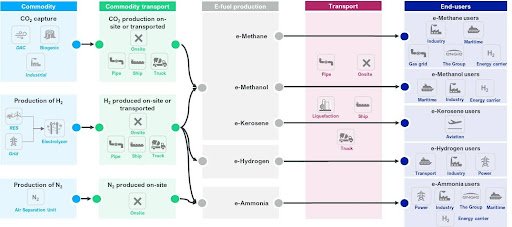

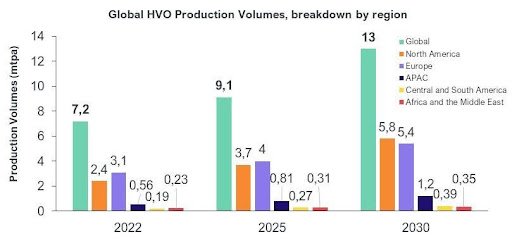

Hence, in 2023 Engie carried out a full desktop study on multiple green fuels presenting an interest for the data center industry. As part of this study, Hydrogenated Vegetable Oil (HVO), 1G biomethane, 2G biomethane, e-methane, green hydrogen, e-ammonia, e-methanol and e-kerosene have been evaluated.

For each of them, the production pathways and the current and trending available volumes of supply per geography have been mapped. The distribution and transportation means have been studied for several key data center locations in South-East Asia, Europe and the US.

Commercial information, notably on the cost of production, have been analyzed, along with their greenhouse gas emissions. Finally, their compatibility with prime mover technologies has been assessed as well as their storage constraints and risks.

With all that data available, Engie and RED Engineering Design are fit to design and implement net-zero carbon data centers in key as well as developing locations for the industry.

Engie is pioneering the production and the use of the future fuels

Engie is already developing and running multiple e-fuel/biofuel production projects with its partners, as well as projects using such fuels either for light transportation, heavy transportation or power generation.

For example, Engie and partners are developing an innovative Carbon Capture and Utilization (CCU) project in Belgium. This project will concentrate CO₂ from an innovative type of lime kiln, and combine it with green hydrogen to produce synthetic methane (or e-methane) that can be injected into the gas grid or used in the transport or industry sectors.

The green hydrogen will be produced by a 100MW electrolysis unit, powered by renewable electricity. This project is one of the largest of its kind in the world and will avoid up to 187,000 tons of CO₂ emissions per year, taking into account emission savings by the use of surplus heat to feed a local district heating network, valorisation of oxygen and contribution to network balancing.

In terms of projects involving the use, and not the production, of new fuels, Engie is developing several on-site power and cooling generation projects, dedicated to data centers, that will run on biomethane. Depending on the location of the project and the production technologies of biomethane, the emission factor of this fuel is actually better than that of photovoltaic panels.

Conclusion

With concurrent knowledge of the supply chains of new green fuels, the overall energy market, as well as running efficient on-site energy equipment, Engie and RED Engineering Design can support the data center industry in the design, financing, installation and operation of their energy infrastructures, future-proofing data centers to accept new concepts and new fuels as they come to market, with a roadmap towards zero-carbon.

To find out more about how Engie and RED Engineering Design can help support your business, please visit www.engie.com.

More from Engie and RED Engineering Design

-

Sponsored Harnessing waste heat: The imperative shift for data centers

Why the pursuit of net-zero hinges on the data center’s ability to harness waste heat

-

DCD>Talks emerging power pressures with Patty Solberg, Engie

DCD's Dan Loosemore talks with Engie's Patty Solberg about emerging power pressures.

-

Sponsored The embodied carbon challenge for truly net-zero data centers

Calculate, compare, contrast. The three C’s to achieving embodied carbon reduction throughout the entire data center lifecycle