Efforts towards climate neutrality, the increasing demand for computing power and the related need for a reliable power supply – challenges in the data center industry are many and multifaceted. The possible solution can be summarized in one term: decentralized energy generation. Electricity generated locally, directly on site, guarantees supply security and quality on the one hand and contributes to grid stability on the other. Produced from renewable energy sources, such as green hydrogen, it also paves the way towards climate neutrality.

What sounds quite abstract becomes very real and tangible with the decentralized solid oxide fuel cell system (SOFC) developed by Bosch. Currently in the pilot phase, Bosch is pushing the industrialization of its SOFC system for sustainable power generation in a future hydrogen economy – and keeps the big picture in mind: In addition to developing fuel cells for stationary applications, Bosch also offers mobile fuel cells, and plans to enter the electrolyzer component business and equips hydrogen filling stations.

Since the Bosch SOFC system is able to run on hydrogen in the future and already today on natural gas and biomethane, data centers are ideally prepared to meet sustainability requirements of today and tomorrow. What’s more, Bosch works together with partners, such as HUB Security, to bundle the SOFC technology in modules that can be scaled individually to electrical demand. “It’s a power supply that can flexibly grow with the IT infrastructure if you want”, explains Marcus Spickermann, head of sales & market development at Bosch SOFC.

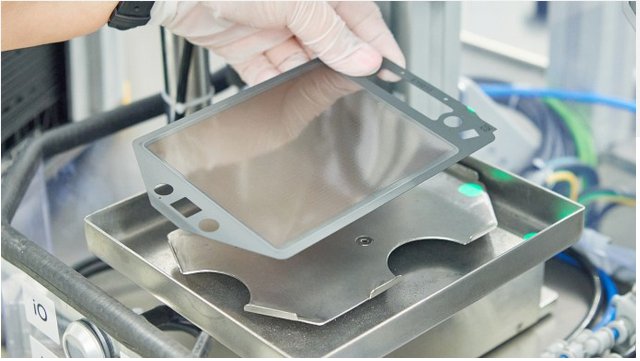

The magic inside the fuel cell

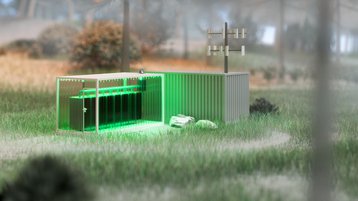

So how does it work? The solid oxide fuel cell technology comes in units, which could be packed into a modular housing to make for a discrete and clean energy solution. Each of the Bosch SOFC prototype units generates around 10kW of electrical power and 3kW of thermal power.

It is possible to scale the systems unit-by-unit all the way up to the megawatt range. But the actual magic happens inside the fuel cell, where fuel goes in and electricity and heat come out. Obviously, the process is a bit more complex as Spickermann explains: “There is an electrochemical reaction that takes place within the fuel cell. Molecules of hydrogen and oxygen gas react with one another creating electricity. This produces direct current (DC) that is converted to alternating current (AC) in the inverter. Heat and water are also generated.”

The DC output could be directly linked to the data center power supply to increase efficiency or, alternatively, it could also be converted to AC. The output is quite impressive: The Bosch SOFC system generates 60 percent electricity and 25 percent heat, so it can reach an overall efficiency of 85 percent.

And, stresses Spickermann, there is no burning process, so minimal exhaust gases in the form of some CO2, in the case of natural gas and biomethane, and just water, in the form of steam, when hydrogen is used. The reaction takes place at operating temperatures of between 500 and 700 degrees Celsius, with excess heat generated at around 200 degrees Celsius. “We are actively looking for different ways to make use of the excess heat.

For data centers, this could mean feeding the excess heat into district heating schemes or using it with absorption chilling solutions that provide cold back to the data center, reducing overall energy demand for traditional cooling infrastructure,” says Spickermann. An aspect that could be highly relevant for data center operations, especially in hot regions such as Middle East and North Africa, or simply for being a good neighbour delivering usable heat.

Early adoption of the SOFC system

What could be a better way to evaluate the technology than testing it in real life? To prepare for future series production, Bosch has initiated a pilot project in Hanover, Germany with HUB Security, which specialises in cyber security, secure IT hardware and secure data center solutions. “We see a grid-independent, scalable, and hydrogen-focused primary power supply as a suitable complement to our edge data center solutions”, says Sem Koeksal, executive vice president at HUB Security. The objective of the pilot, starting in early 2023, is to develop a blueprint of an SOFC module that can be rolled out as a primary power supply to data centers around the world.

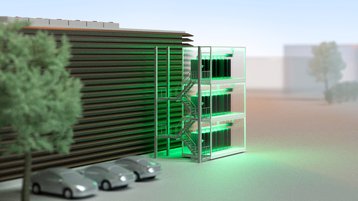

The Bosch SOFC system can power both Edge as well as core data centers. As both are confronted with the challenge that the surrounding operational infrastructure has to meet the growing server infrastructure, the flexibly scalable SOFC is a perfect fit.

The advantage of SOFC is that only what is necessary need be installed. The SOFC systems are flexible in terms of location and scalable as required. In line with demand, they can be adapted to the existing IT infrastructure. “The scalability of the Bosch SOFC distinguishes us from traditional power architectures, in which infrastructures are already installed on day 1, which are designed for the maximum power of the data center and are therefore oversized for a long time”, explains Koeksal. The modular approach enabled by the Bosch SOFC system not only saves resources, but also minimizes capital commitment.

And, adds Koeksal, the Bosch SOFC system helps data center operators to become independent from the energy grid, solving problems around power shortage while also increasing site selection flexibility and minimizing time-to-market for new data centers. Currently, most data centers obtain their primary energy from the power grid. If there is a power outage, backup power systems often take over power generation in the meantime. SOFCs could not only replace backup power systems, such as diesel generators, they could offer a resilient alternative to the conventional power grid by supplying data centers with primary energy.

Spickermann explains: “With island mode, data centers can be operated completely independently of the power grid. After all, they generate their own power directly on site.” Sounds like the future? Electrical losses due to substations and transformers will then definitely be a thing of the past. Another advantage: the built-in redundancies of Bosch’s hydrogen fuel cell technology means that backup generators are no longer necessary, adding to both the sustainability and cost arguments in favor of solid oxide fuel cell technology.

Being able to install it now and run it on natural gas or biomethane, and to use green hydrogen in the future, is another benefit. “In some countries, we already see the possibility in the medium term – maybe in a few years – to use green hydrogen as fuel for SOFCs for data centers. But in other countries this may take longer.

Nevertheless, using natural gas or biomethane, possibly with an admixture of H2, can help to reduce emissions compared to traditional ways of grid-based power supply,” says Koeksal. And this can be done well before the challenging net-zero carbon emission deadlines of 2030 or 2035 come around.

Turning the hydrogen vision reality

Although green hydrogen is not yet available, pilot projects like the one being run by Bosch and HUB Security show that progress is being made in turning the vision of a future decentralized hydrogen power supply reality.

This partnership combines relevant competences. HUB Security is experienced with data center power architectures, as their solutions include secure edge data center facilities, as well as the infrastructure for secure, reliable and sustainable on-site power generation.

And Bosch is a global player that has already successfully launched a number of new innovations on the market. It has been designing, developing and manufacturing industrial products since 1886. This comes with engineering know-how and expertise in production procedures relevant for fuel cells. The company is known for its decades of experience with industrializing complex technological products on a large scale. These strengths are now applied to integrate the SOFC system into data center operations.

Where the demand is high, as Koeksal knows, “We see great demand from European, US, and MENA-based edge, cloud and colocation data centers. A global rollout is intended as we complete the pilot.”

Spickermann from Bosch summarizes: “The pilot project and this partnership with HUB Security are the first steps to integrate our Bosch SOFC into holistic data center solutions. But the potential goes far beyond, both in the data center sector as well as in other application areas.”

To find out more about solid oxide fuel cell technology, check out Bosch's newly launched specialist SOFC website!

More...

-

Bosch plans €1bn hydrogen fuel cell push

Will build 100 stationary fuel-cell plants

-

Can data centers catalyze a hydrogen market?

The hydrogen economy has a much bigger role than providing backup power for data centers. But it has to start somewhere

-

Could hydrogen kill off diesel?

Microsoft ran 10 racks on a hydrogen fuel cell for 48 hours. Here’s what comes next