In the ever-evolving world of network infrastructure, increased power integration and emissions compliance are of utmost importance. The current trajectory of fiber densification, driven by higher speeds and increasing fiber counts, is pushing existing technology and network topographies to their limits. Industry collaboration is necessary to overcome these roadblocks and drive the industry forward.

For instance, the recently released Base 16 fiber optic cabling technology, essential for multimode 400GBASE SR8, is making waves in the industry. The technology aims to enhance the density of fiber connections to servers.

However, for the full benefits of Base 16 to be achieved, it necessitates supporting innovations across the board.

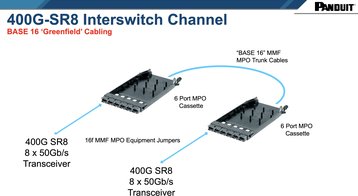

Base 16 represents a significant advancement over its predecessors, Base 12 and Base 8. With sixteen fibers – eight for transmitting and eight for receiving – it marks a notable departure from previous technologies.

The uniquely offset connector key ensures compatibility with other Base 16 components, though is not directly compatible with Base 8 or Base 12 components without conversion media.

The industry has so far struggled to maximize the deployment of multimode short-reach 400-gigabit modules (400GBASE-SR8). However, angled-polished multi-fiber push-on (MPO) connectors, designed to support multi-fiber applications, can minimize back reflection (optical return loss) – crucial for maintaining signal integrity associated with multimode fiber.

Deploying a 400G connection using the SR8 interface allows the high-speed 400G connection to be divided into eight separate 50G connections. This enables more granular and versatile network designs, connecting multiple devices or systems each requiring a 50G connection, rather than a single 400G connection.

With the growing availability of cassettes that convert high-density 16-fiber MPO connections into multiple LC connections, these cassettes can provide 50G Ethernet connectivity to users.

Currently, data centers often use a setup where 400G Ethernet switches connect to servers with 50 GbE links. A typical configuration includes a pod consisting of 16 cabinets, each holding 32 servers. Each server is connected via one 50 GbE link.

This setup follows the traditional model where each cabinet has a top-of-rack (TOR) switch supporting 32 or more servers. While this delivers high performance, it is an expensive deployment strategy.

The latest high-density technologies, using ports to break 400G connections into 50G connections, offer system architects and installers the ability to leverage middle-of-rack (MOR) switch deployment. In this way, the number of MOR switches can be significantly reduced, rather than needing TOR switches in every cabinet. Thus, users can deploy 400G SR8 modules to distribute 50G connections to servers.

The increasing bandwidth and fiber speeds have diverse impacts on infrastructure architecture. To optimize the performance of the infrastructure ecosystem, faster server racks require tailored support systems, such as intelligent power distribution units (PDUs), to ensure efficient power distribution.

Large multinational organizations, whether enterprises or data centers, often consolidate their infrastructure for procurement and installation efficiency.

With the rising power density in rack environments and potential variations in local utility supply, there may be a need to adjust the voltage phasing of racks to accommodate servers and related systems.

Density requires support

The latest universal PDUs (uPDUs) offer easily switchable power capabilities, accommodating input voltages ranging from 208V to 415V in both single-phase (1PH) and three-phase (3PH) supplies, making them suitable for global use. During installation, users simply select the facility-side cord set to match the power requirements, allowing for scalability as needs grow.

Typically, cabinets feature two PDUs supplying power to the equipment. Installers can now switch off the uPDU, transfer all equipment to the secondary PDU, and make necessary adjustments to the power in lead – such as changing current rating or phase – without altering connections to the uPDU.

Once adjusted, the uPDU can be powered back up. Additionally, the uPDU can be remotely managed through its built-in web server and integrated with DCIM software for off-site data collection and alert monitoring.

The industry has so far struggled to maximize the deployment of multimode short-reach 400-gigabit modules (400GBASE-SR8).

However, angled-polished multi-fiber push-on (MPO) connectors, designed to support multi-fiber applications, can minimize back reflection (optical return loss) – crucial for maintaining signal integrity associated with multimode fiber.

Real-time data collection is becoming central to organizational reporting, both internally and externally mandated.

By using structured data, organizations can track changes in key factors such as power usage and CO2 emissions over time. This enables them to manage changes effectively, reduce CO2 emissions, and use power more efficiently.

From a compliance perspective, data centers must adhere to various regulations. The latest dashboards enable administrators to set these rules, allowing the system to monitor and respond when environmental thresholds are exceeded. Another important aspect is the use of 'what-if' scenarios.

These scenarios are crucial for evaluating changes in architecture, such as introducing more power-efficient devices with lower power consumption and CO2 emissions. They help guide users in making recommendations and decisions for future deployments.

Rapid cable ID mapping

Increasingly dense cable environments can be easily documented and mapped, facilitating auditing at any point in the infrastructure's lifecycle.

As a leading manufacturer of fiber and copper cables, Panduit understands the challenges faced by installers and service engineers in environments with dense cable runs and cabinet connectivity.

Cable network mapping is essential for reducing human error during cable disconnects, a common cause of system downtime. Adding two extra labels at the source of each patch cord has revolutionized cable logging and tracing.

By using a software app, installers and maintenance engineers can scan these labels with a Bluetooth scanner, associate the barcode with the port, and save the information to a database. This creates a detailed profile of the network's configuration. This method is a cost-effective way to document and maintain an accurate, up-to-date record of the cable environment.

The increasing cable density and data rates in rack environments mean that any downtime can be a significant technical, financial, and reputational issue.

However, there are straightforward opportunities to leverage higher speeds and more powerful server capabilities. Base 16 technology enables faster throughput for higher data rates – essential for today’s data-intensive applications.

Additionally, the need for sustainability reporting requires more data capture within the ITE environment. Manufacturers and suppliers to enterprises and data centers recognize the necessity to provide platforms that support and facilitate data gathering across the infrastructure. This enables customers to better integrate systems and maximize their resources.

More from Panduit

-

-

Sponsored Power crisis equals UPS opportunity

-