By pairing an air-cooled, magnetic bearing chiller and mission-critical air handling units with the sophisticated AI capabilities of open-source digital platforms, data centers can reduce energy use by allowing for a dynamic – rather than static – chilled water setpoint.

The primary objective for any data center is flawless data processing; critical to achieving that objective is high reliability and maximized uptime. However, to mitigate the effects of climate change, another attribute has become equally important – minimized environmental impact. Since maintaining uptime has traditionally required significant energy and resources, these goals seem to be at odds.

Data centers are one of the most energy-intensive types of buildings, consuming 10 to 50 times the energy per floor space of standard commercial office buildings and collectively using about two percent of the nation’s total electricity consumption. As technology leaders make significant net-zero and water commitments, they are seeking new innovations to reliably reduce energy and resource use.

Aside from the electricity that servers consume, HVAC equipment is responsible for as much as 40 percent of electricity use in data centers. To operate sustainably and profitably, it’s critical these facilities optimize HVAC energy efficiency while ensuring data center uptime.

The latest innovations in HVAC and smart building technology make this outcome possible, cutting energy and water usage, carbon emissions, and costs while ensuring the highest reliability. Mission-critical, computer room air handling units paired with an air-cooled, magnetic bearing chiller, digital solutions, and building automation technology can significantly improve data center sustainability while maintaining an environment that supports reliability and uptime.

Maintaining cold aisle temperatures

The temperature of the cold aisle determines how aggressively HVAC equipment and server fans must work, and therefore how much power they consume, to ensure the proper volume of air moves through servers to remove heat. A higher cold aisle temperature results in lower chiller power consumption. A lower cold aisle temperature results in a smaller volume of airflow being needed and less fan power consumption for the air handling unit fans and server fans.

To prevent hot spots in a data center’s white space and ensure uptime, data center cooling strategies have historically favored lower cold aisle temperature and higher air flows — even beyond what’s needed. This excess airflow acts as a buffer for an application that is close to the edge of the requirement. For example, if a certain server has a higher-than-usual load on it, it may starve the cold aisle of cold air and may overheat. The extra airflow provides a safety net, but it also wastes energy.

Advances in server technology have made it possible for the latest generation of servers to operate at high ambient conditions in warmer cold aisles. Servers that can operate in a greater temperature range make it possible for a broader range of acceptable cold aisle temperatures.

By optimizing the cold aisle temperature, a data center can consume the minimum power required to cool it. Currently, this temperature is a static number. However, research into the effects of a dynamic cold aisle temperature proves that a dynamic cold aisle temperature can deliver optimum cooling according to the ambient conditions in the data center load at any given time – and the technology to do it is available now. For instance, when it’s very cold outside, there is an opportunity to use economization or free cooling and simultaneously lower the chilled water setpoint and lower the cold aisle temperatures.

This reduces airflow and power consumption from the computer room air handler as well as server fans. When a data center uses a static chilled water setpoint and a static cold aisle temperature, this opportunity is lost.

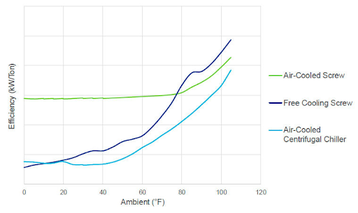

On the hottest afternoons of the year, the chiller power consumption is highest because the lift on the chiller is high. Chiller lift refers to the difference in pressure between the refrigerant in the condenser and the refrigerant in the evaporator. At higher lifts, the compressor consumes higher amounts of power to drive the thermodynamic cycle.

The lift may be reduced by raising the chilled water setpoint and the cold aisle temperature for a few hours in the afternoon. This reduces the power consumption by the chiller compressor(s). The industry uses the term temporary excursion from ASHRAE Thermal Guidelines for Air Cooling of IT Equipment.

The pairing of an air-cooled, magnetic bearing centrifugal chiller and mission-critical, computer room air handlers with an open-source digital platform and building automation system can drive cold aisle temperatures that suit data center loads at any given moment. A dynamic chilled water setpoint, and a dynamic cold aisle temperature overall, help optimize a data center’s power consumption without risking the uptime of the data center. This method of continuous optimization could lead to the best real-time energy efficiency of the data center while providing cold aisle temperatures that help maintain uptime.

Innovative technology for an evolving industry

Historically, data centers have used chillers and other HVAC equipment that were designed for comfort cooling, not data centers. In comfort cooling, chilled water setpoints are around 44 degrees fahrenheit. However, server manufacturers are becoming more comfortable with processors and motherboards operating at higher temperatures, which means they can be cooled with chilled water upwards of 80 degrees fahrenheit.

Innovations in chillers for data center applications make it possible for chilled water setpoints to be anywhere from 70 to 80 degrees fahrenheit, and sometimes even higher. This reduces power consumption and increases the number of annual hours when free cooling can be used to significantly reduce the amount of power that is consumed by data centers throughout the year.

Designed specifically for data centers, air-cooled, magnetic-bearing centrifugal chillers are optimized for increased temperatures inside the white space and the lifts that are prevalent in the data center industry today. They can deliver chilled water temperatures that are upwards of 80 degrees fahrenheit and cater to a low lift, resulting in greater energy efficiency.

While most data centers use air-cooled chillers that have free cooling coils to benefit from lower ambient conditions, air-cooled, magnetic-bearing centrifugal chillers can operate at inverted conditions and provide free cooling without additional free cooling coils. Free cooling coils that are added to the condenser of the chiller can lead to inefficiencies and additional pressure drops, as well as heavier equipment and a larger carbon footprint. The weight they add to the chiller is embodied carbon, from the metal that makes up the coils, to heavier shipping and rigging weight, to the need for a building structure that inherently has more steel in it to support additional weight on the rooftop. Using a chiller that is lighter and provides inverted-operation-free cooling positively impacts the carbon footprint of the building itself in many dimensions.

The friction-free, magnetic drive benefits uptime, as well. If power is interrupted, a typical chiller can take up to 10 minutes to restart. In comparison, magnetic bearing centrifugal chillers have much faster compressor restart times and can return to full load in as few as three minutes after power is restored. Because air-cooled, magnetic-bearing centrifugal chillers use a variable-speed drive, there is no inrush current. This means a fast, controlled return to full capacity and setpoint.

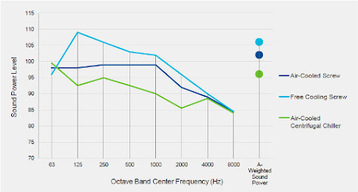

To further improve data center sustainability, air-cooled, magnetic-bearing chillers produce notably less sound than many screw chillers, and some use R-1234ze, a refrigerant with ultra-low global warming potential (GWP).

When connected to an AI-based solution, air-cooled magnetic bearing centrifugal chillers combined with highly efficient mission-critical computer room air handlers designed with electronically commutated motors (ECM) can match cold aisle temperature with the real-time load and optimize energy use from moment to moment. Having a dynamic chilled water setpoint and cold aisle temperature optimizes energy use without risk to data center uptime.

Optimizing energy use based on real-time conditions

Intelligent digital services, like that provided by an artificial intelligence (AI)-based solution, integrated with air-cooled magnetic bearing centrifugal chillers and high-efficiency mission-critical computer room air handlers, provide the most optimized energy solution. Coupled with a dynamic water setpoint and a routine chilled water reset strategy offers even further energy savings. These solutions optimize airflow based on real-time conditions and can significantly reduce a data center’s energy use.

As part of a digital platform, an AI-based solution can be either an advisory or a supervisory function sitting on top of the building management system (BMS). There, it ensures that data center personnel can evaluate the real-time data center loading and real-time data center requirements around the ambient conditions, as well as know the historical loading patterns or trends. Equipped with this valuable information, facility managers can ensure the system is operating as efficiently as it can.

A chilled water reset strategy can help reduce energy use during peak demand periods in data centers that experience high ambient temperatures. A chiller’s power consumption depends on lift, and lower lift means less energy use. During the hottest afternoons of the year, a low chilled water temperature is required to cool the data center. To achieve this, lift and power consumption are typically high. However, the chilled water setpoint can be adjusted to a higher temperature for four or five hours in the afternoon to improve system energy efficiency while relying on a slight ramp-up of the high-efficiency ECM fans in the computer room air handlers.

This chilled water reset deviates from standard conditions and isn’t permitted by some service-level agreements. To improve overall efficiency and data center sustainability, it’s important to include chilled water reset for a set number of hours per year in service-level agreements.

Using historical trends, an intelligent cooling system can anticipate and prepare for the next loading change. For example, if a data center consistently generates a lot of heat around 8 AM, the system can be automated to gradually ramp up capacity starting at 7 AM rather than running at 100 percent capacity at 7:59 AM. This gradual ramp-up minimizes system spikes, improves energy efficiency, and can even extend equipment life.

A combination of digital solutions, connected equipment, and building automation technology can make data centers smarter and more sustainable. These solutions allow facility managers to continuously monitor equipment health and energy consumption in real-time while automating key processes. Some solutions also offer easy-to-read dashboards that display trends and notify assigned personnel when set parameters deviate from assigned values. That allows facility teams to address issues, identify opportunities for energy savings, and drive outcomes that matter most.

Improving energy efficiency and uptime – simultaneously

Technology leaders have very strict sustainability goals with aggressive deadlines to reach them. It’s critical that data centers are equipped with innovative solutions to help achieve those goals as quickly as possible. Purposefully designed air-cooled, magnetic bearing centrifugal chillers combined with mission-critical, computer room air handlers driven by artificial intelligence can optimize sustainability according to real-world, white space conditions and significantly improve data center efficiency while maintaining uptime.

As servers become more capable of operating at high ambient conditions and data center owners and operators become more comfortable with warmer cold aisles, it’s essential that HVAC equipment be ready to operate at higher chilled water setpoints and higher cold aisle temperatures. This shift in a long-held design mindset presents the opportunity to create a smarter, more sustainable data center architecture that collaborates and empowers overall energy efficiency and reliability. Air-cooled, magnetic-bearing centrifugal chillers, mission-critical computer room air handlers, and a logic-based BMS can grow and evolve with data centers, providing continuous improvement today and tomorrow.

More about Johnson Controls

-

Johnson Controls launches data center solutions business

New organization has appointed Todd Grabowski as CEO

-

-

Air cooling is here to stay

Why has DCD been talking about air cooling this week?